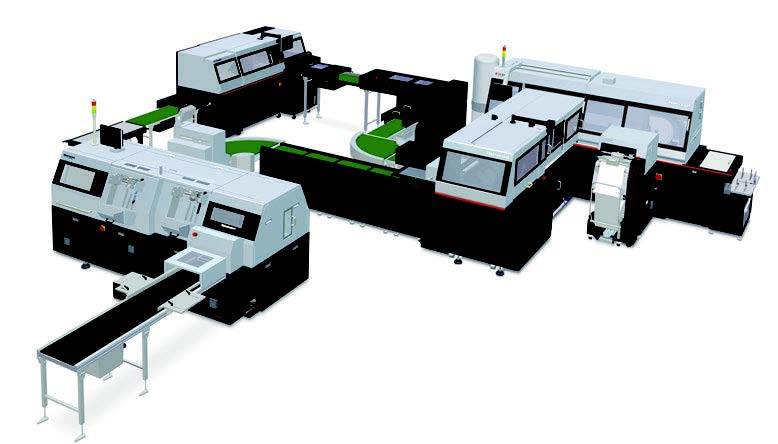

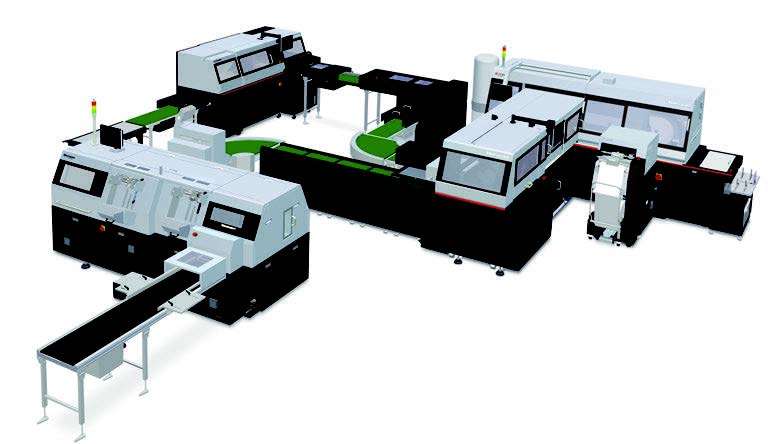

Expand your binding capabilities with the Horizon GF-500 Gauze Feeder, the perfect solution for adding reinforced spine durability to books produced on the Horizon BQ-500 Perfect Binder. Designed for seamless integration and full automation, the GF-500 applies gauze to the book block—an essential step for producing strong, long-lasting case bound books.

Key Features

🔷 Fully Automated Gauze Application – Adjust gauze width and length automatically based on book block dimensions

🔷 Touchscreen Control – Switch between gauze and soft cover production without removing the feeder

🔷 Auto De-Curling System – Dynamically adjusts for gauze roll diameter for smooth, consistent application

🔷 Gauze Alignment Control – Maintains precise gauze positioning throughout production

🔷 On-the-Fly Adjustments – Supports variable thickness binding jobs without downtime

Specifications

| Specification | Detail |

|---|---|

| Compatibility | Horizon BQ-500 Perfect Binder |

| Operation Mode | Inline, fully automated |

| Gauze Width/Length Control | Automatic, based on book block dimensions |

| Switchable Operation | Gauze or softcover production via touchscreen |

| De-Curling System | Automatic, with force adjustment |

| Alignment System | Gauze alignment control for precision application |

Applications

📦 Case binding for hardcover books

🖨 Reinforced spine book production

⚙️ Industrial perfect binding enhancement

Benefits

✅ Adds critical spine reinforcement for case binding durability

✅ Enables fully automated gauze tipping with minimal operator input

✅ Maintains consistent output through auto adjustment systems

✅ Eliminates production downtime when switching between job types

✅ Enhances overall quality and longevity of finished books

Contact Us