Automatic Platen Die Cutter

The AeroDieCut is a compact, all-in-one platen die cutter designed for fast, precise finishing of printed cards, packaging, labels, and tags. Ideal for digital and offset print environments, it supports multi-up layouts, high-speed cutting at up to 1,000 sheets per hour, and features MBM’s Tri-Suction Feeder, cut mark detection, and touchscreen job recall. Easier to use than traditional clamshell die cutters and more productive than laser or plotter cutters, the AeroDieCut simplifies high-end finishing for commercial print shops.

Key Features

🔷 Platen Die Cutting System – Delivers crisp, consistent cuts, creases, and perforations in one pass.

🔷 Tri-Suction Feeder with Ultrasonic Sensors – Prevents double-feeds and supports image shift compensation.

🔷 Multi-Up Step & Repeat Mode – Maximizes die usage and sheet efficiency, lowering per-job costs.

🔷 4.3” Color Touchscreen – Stores up to 100 jobs with fast, intuitive setup.

🔷 Waste Separator and Delivery Conveyor (Optional) – Removes scrap and speeds up collection.

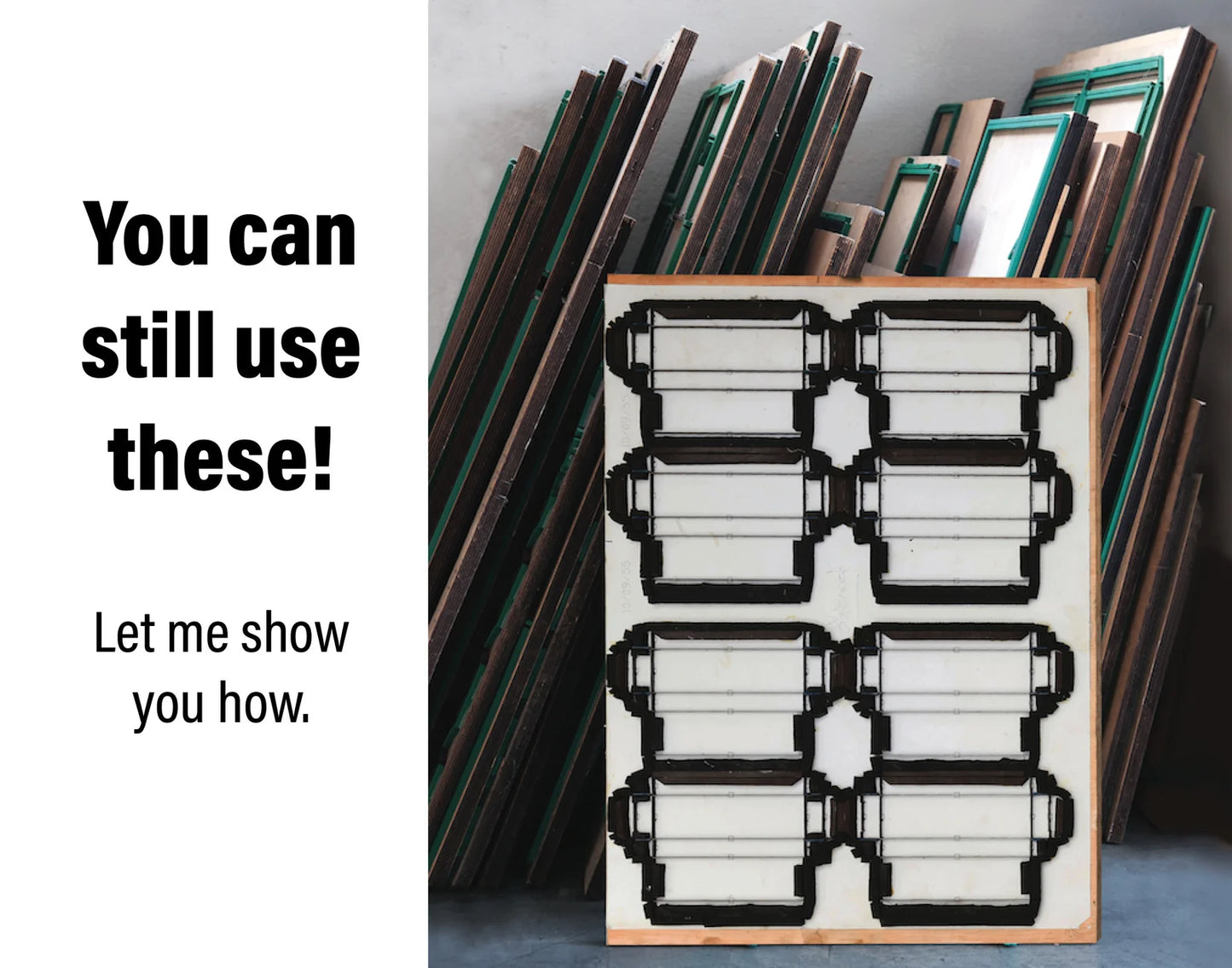

🔷 Die Storage Rack and Chase Adapter Included – Organized die management for faster job changeover.

🔷 Compact Footprint – Fits comfortably in digital print rooms, packaging labs, and in-plant setups.

🔷 Operator-Focused Safety Design – Designed with simplicity and safety at its core.

Specifications

| Specification | Details |

|---|---|

| Max Speed | Up to 1,000 sheets/hour* |

| Max Paper Size | 14.3” x 20.25” |

| Max Finishing Area | 12.2” x 19” |

| Paper Weight Range | 120–400 gsm* |

| Die Board Size | 13.75” x 21.65” |

| Die Board Thickness | 7” |

| Cutting Rule Height | 0.91”–0.93” |

| Power Requirements | 110–120V, 50/60 Hz |

| Dimensions (D x W x H) | 42” x 106” x 43” |

| Weight | 903 lbs |

*Output and compatibility may vary based on paper coatings, stock, and power supply.

Applications

💌 Die-Cut Greeting Cards & Invites – Create unique shapes and folds with clean creases and precision edges.

📦 Packaging & Folding Cartons – Short-run production of boxes, trays, and product sleeves.

🏷 Tags & Labels – Efficiently produce die-cut tags, loyalty cards, or shaped labels.

🎟 Tickets, Coupons & Specialty Items – Combine cutting, creasing, and perforating in a single pass.

Available Options

📍 Waste Separator Unit – Redirects scrap away from finished product stream.

📍 Delivery Conveyor Table – Speeds up batch stacking and collection.

📍 Custom Chase & Plate Sets – Organize die cutting components for frequent job changes.

📍 Die Board Storage Rack – Keeps tooling organized and ready to access.

Benefits

✅ Cuts, creases, and perforates in a single step, reducing time and handling.

✅ Faster than laser and digital plotter systems for repeated shapes and media.

✅ Works with custom dies while offering automated registration and job recall.

✅ Compact and easy to use, suitable for both new operators and seasoned pros.

✅ Scales with demand using step-and-repeat and optional waste management tools.

Contact Us