Mitsubishi FREDIA EcoWz — 4-Up Polyester CTP with Integrated ECO Processor

Fully-automated internal-drum CTP for high-quality 4-up plates. Dual on-line roll magazines, integrated punching, and ECO processing deliver speed, stability, and low running cost.

Key Features

🔷 Up to ~30 plates/hour at 2540 dpi; resolutions to 3000 dpi

🔷 Two roll magazines online; automatic sizing and integrated press punches

🔷 ECO processor with thin-layer activator/stabilizer for cost savings

🔷 Supports process color work and LED-UV printing

🔷 Compact installation with simplified maintenance

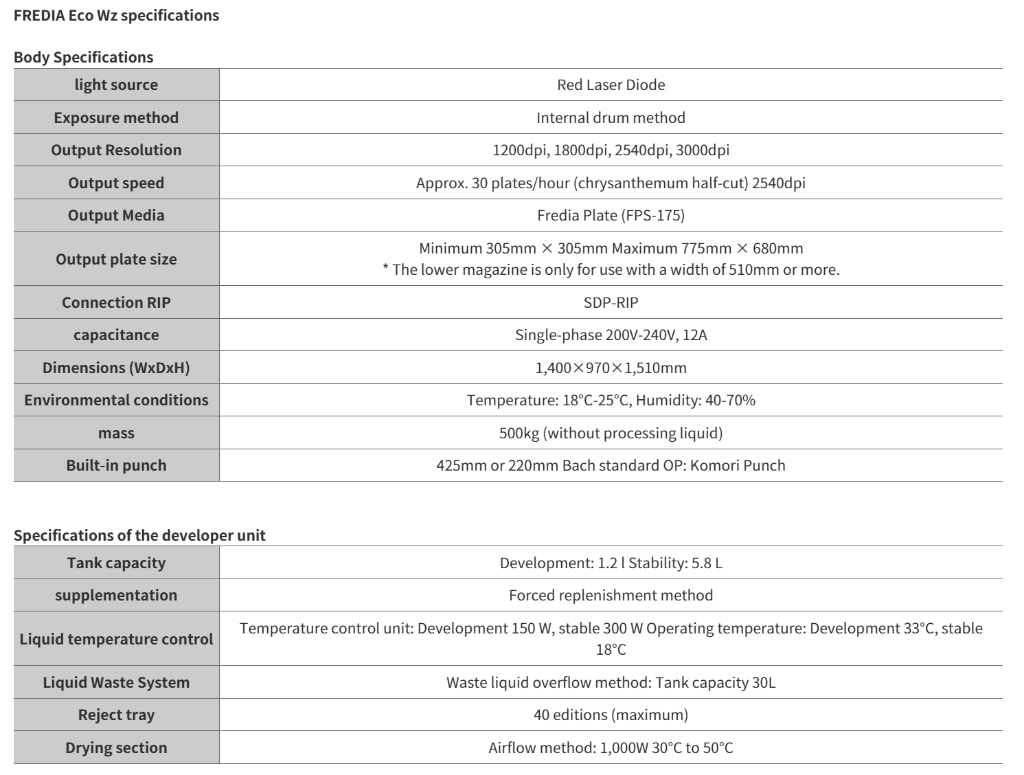

Specifications

| Plate type / Base | FREDIA Plate™ polyester (FP-175); 0.20 mm |

| Plate sizes (min–max) | 305 × 305 mm to 775 × 680 mm (2-up to 4-up) |

| Resolution / Speed | 1200 / 1800 / 2540 / 3000 dpi; ~30 plates/hr @2540 dpi |

| Screen ruling / Tint | Up to 230 lpi; 3–98% tints |

| Run length | Up to ~20,000 impressions (FPS-175, typical conditions) |

| Punching | Bacher 425/220 pitch standard; Komori 550 optional |

| Processor / Chemistry | Integrated ECO processor; Activator SDP-EAC IIN (1.2 L), Stabilizer SDP-FST II (5.8 L) |

| Material supply | 2 roll magazines on line; automatic sizing/cutting |

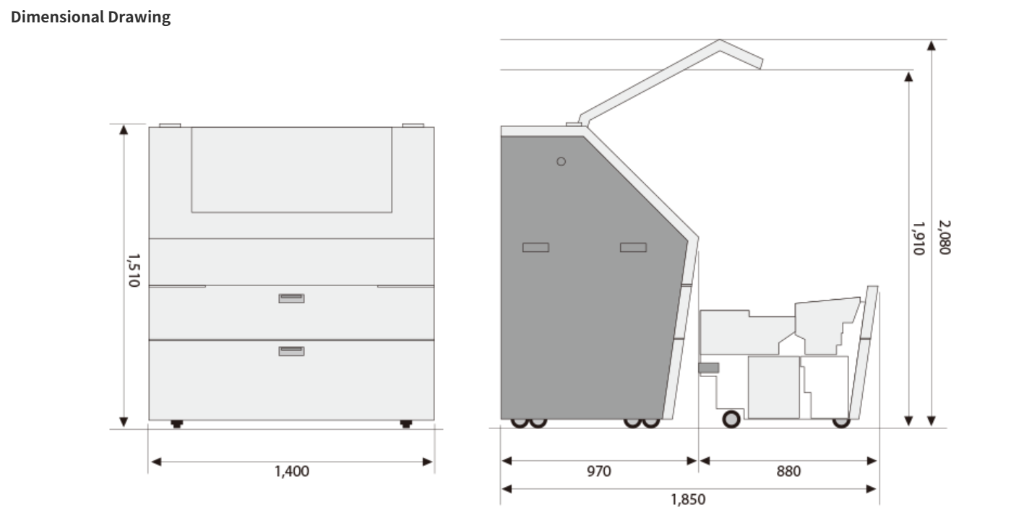

| Power / Size / Weight | AC200–240V, ~12A; 1400 × 970 × 1510 mm; ~500 kg |

Applications

🎨 4-color process plates for multi-press environments

🏭 LED-UV, commercial, and packaging workflows

🧩 Shops needing two on-line rolls to swap sizes with minimal waste

Available Options

📌 Additional punch formats; RIP configurations

📌 Plate and chemistry packages for ECO processing

Benefits

✅ Two on-line rolls reduce changeover and waste

✅ ECO processor lowers chemistry use and running costs

✅ High quality output suitable for process color and LED-UV

Contact Us