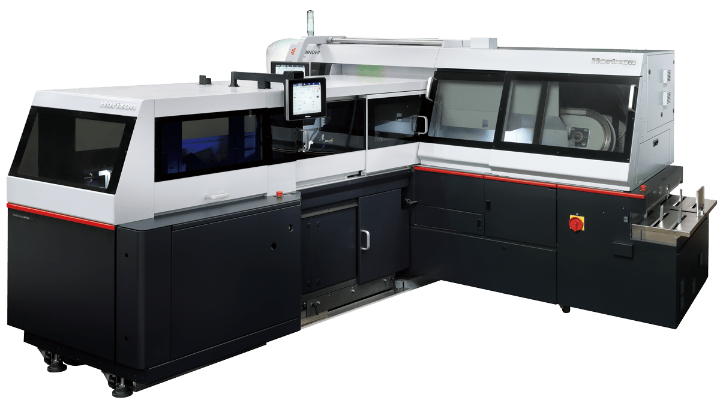

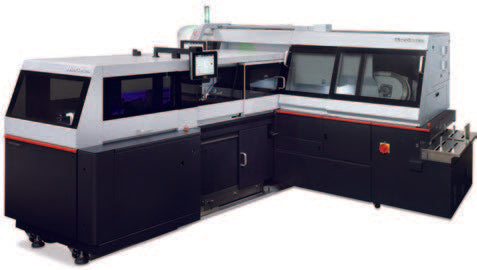

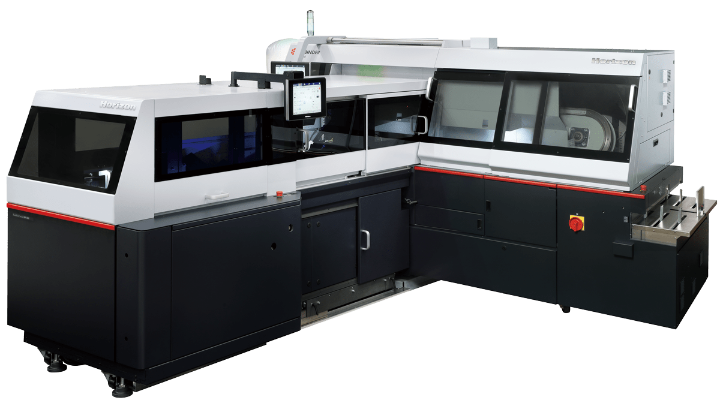

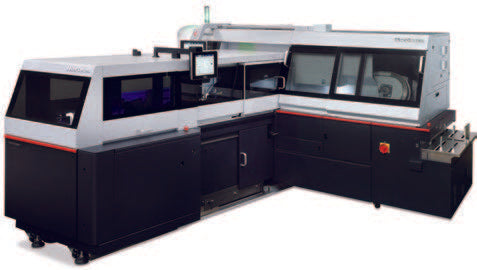

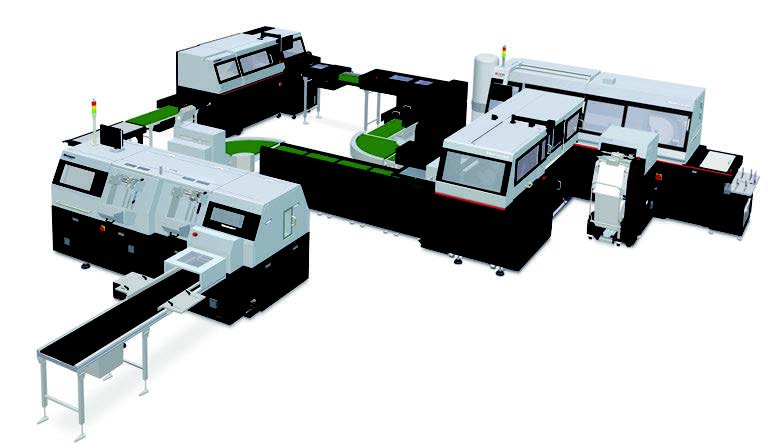

Streamline your binding workflow with the Horizon LBF-500 Book Block Feeder—an essential automation upgrade for the Horizon BQ-500 Perfect Binder. Designed to reduce manual labor and improve production consistency, the LBF-500 automates the loading of book blocks into the binder using a smart, angled jogging conveyor system. Whether feeding from inline equipment or operator-loaded stacks, the result is faster, cleaner, and more efficient book production.

Key Features

🔷 Automated Book Block Feeding – Eliminates hand loading by delivering book blocks directly into the binder

🔷 Angled Flighted Conveyor – Gently jogs and aligns each block for optimal binding precision

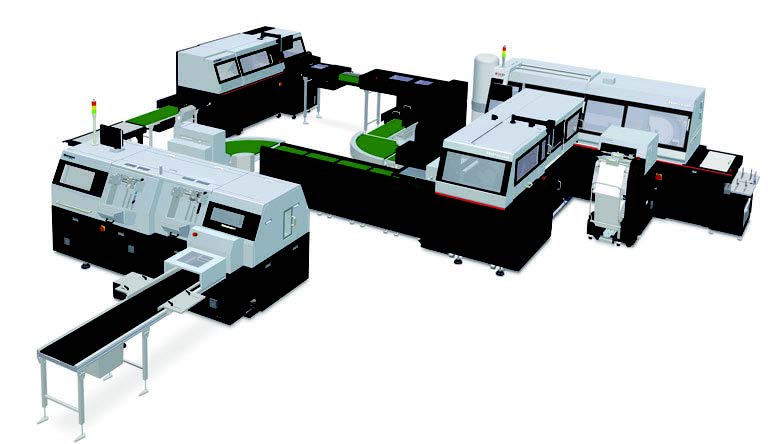

🔷 Inline Integration Ready – Seamlessly connects to upstream book block creation systems

🔷 Secondary Jogging – Ensures every block is perfectly aligned before binding

🔷 Intelligent Feeding Logic – Reduces human variability, enhancing overall book quality

Specifications

| Specification | Detail |

|---|---|

| Compatibility | Horizon BQ-500 Perfect Binder |

| Operation | Inline or operator-fed |

| Transport Mechanism | Angled flighted conveyor with jogging system |

| Jogging | Primary in-feed jog + secondary binder jog |

| Market Debut | 2019 Smart Factory event (Kyoto, Japan) |

| Region Availability | North America, Global |

Applications

📦 Automated perfect binding setups

🖨 High-volume book production workflows

⚙️ Operator-free or minimal-labor book block feeding

Benefits

✅ Replaces manual feeding with consistent, automated delivery

✅ Enhances speed and reduces labor in bookbinding operations

✅ Improves alignment and reduces inconsistencies in final output

✅ Enables smart factory integration with upstream block production

✅ Supports both inline and standalone configurations

Contact Us