Product Overview

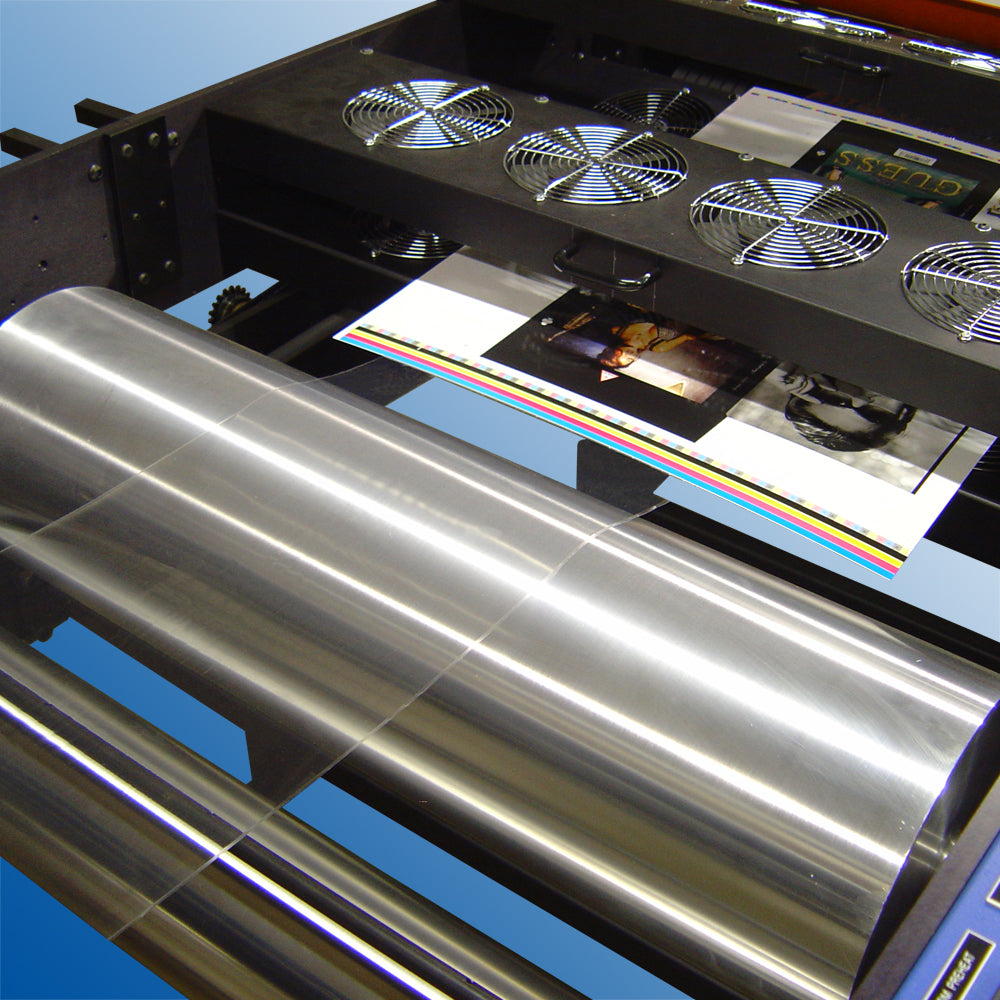

The Double Kote HS is a high-speed, two-sided sheet-fed laminating system engineered for industrial productivity. It handles sheet sizes from 8.5" × 11" (216 × 279 mm) up to 31" × 40" (787 × 1016 mm) and runs films from 1.3 mil (33 µm) to 15 mil (381 µm) at speeds up to 125 fpm (38 m/min). Designed for single-operator efficiency, the complete line integrates feeder, registration table, laminator, cutter, and jogger for continuous throughput and outstanding clarity.

Key Features

🔹 Handles sheets from 8.5" × 11" to 31" × 40" (216 × 279 mm to 787 × 1016 mm)

🔹 High-speed operation up to 125 fpm (38 m/min) for true production output

🔹 Accepts 1.3 – 15 mil films (PET / OPP / PVC)

🔹 Integrated belt registration table for consistent feeding and gap control

🔹 Maintenance-light heated nip design with precise temperature regulation

🔹 Dual fan banks and chill roller for superior clarity and flatness

🔹 One-person workflow with automatic feeder, cutter, and jogger

🔹 Fast film changeover in approximately 3–5 minutes

Specifications

| Speed | Up to 125 fpm (38 m/min) |

| Sheet Size Range | Min 8.5" × 11" (216 × 279 mm); Max 31" × 40" (787 × 1016 mm) |

| Film Thickness | 1.3 – 15 mil (33 – 381 µm) |

| Compatible Films | PET, OPP, PVC |

| Max Film Roll Width | 31" (787 mm) |

| Max Film Roll Diameter | 18" (457 mm) |

| Warm-Up Time | Approx. 15 minutes |

| Pre-Heat Temperature | 70 – 300 °F (21 – 149 °C) |

| Nip Roller Temperature | 70 – 250 °F (21 – 121 °C) |

| Substrate Range | 80 lb text – 20 pt board |

| Feeder Pile Height | ~29" (737 mm) |

| Laminator Dimensions | 94.5" L × 55" W × 61" H (2400 × 1400 × 1550 mm) |

| Feeder Dimensions | 53" L × 59" W × 47" H (1346 × 1499 × 1194 mm) |

| Table Dimensions | 49" L × 46" W × 37" H (1245 × 1168 × 940 mm) |

| Cutter Dimensions | 41" L × 27" W × 24" H (1041 × 686 × 610 mm) |

| Jogger Dimensions | 53" L × 59" W × 47" H (1346 × 1499 × 1194 mm) |

| Required Clearance | Minimum 5′ (1.5 m) on all sides |

| Electrical | 230 V AC, 3-phase, 80 A (with neutral & ground) |

| Compressed Air | 12 cfm at 100 psi (0.34 m³/min at 6.9 bar) |

Applications

- Book covers, brochures, and catalogs

- Menus, ID cards, waterproof handouts

- Rigid displays, signage, and mounting boards

- High-volume lamination for commercial print and packaging

Available Options

- Additional film shafts and widths

- Inline slitter and cutter configurations

- Custom jogger and stacker setups

- Installation, operator training, and service plans

Benefits

- Achieve true production speeds with reliable throughput

- Wide sheet and film compatibility for varied applications

- Integrated chilling ensures flat, crystal-clear results

- Streamlined one-person operation minimizes labor cost

- Quick setup and maintenance-light roller design

Contact Us