Industrial Laminator

The Foliant Castor 530 SF is a high-speed, heavy-duty industrial laminator engineered for demanding print environments. With a maximum speed of 180 ft/min and throughput up to 4,600 sheets per hour, this compact powerhouse features a suction stream feeder, fast bump separator, micro-adjustable air shaft, and PLC-controlled automation. Its walk-in service area, wide film compatibility, and support for paper weights up to 600 gsm make it a premier solution for offset and digital lamination.

Key Features

🔷 Suction Stream Feeder – OMRON servo-driven with 25.5” pile capacity and electronic overlap control.

🔷 High-Speed Bump Separator – Automatically separates laminated sheets with fast-cycling rollers.

🔷 Micro-Adjustable Film Shaft – Tool-free positioning and quick changeover for rolls up to 9,842’.

🔷 Dual Roller System – Heated chrome roller with 4 internal heaters and pneumatically adjustable pressure.

🔷 In-Run Adjustable De-Curl Bar – Includes unique "U" crossbar for flat sheet processing.

🔷 Walk-In Service Section – Provides easy access for cleaning and roller maintenance.

🔷 Wide Film Support – Laminates BOPP, Nylon, and PET films from 20–42μm.

🔷 Touchscreen PLC Interface – Omron-powered control system with icon-based navigation.

Specifications

| Specification | Details |

|---|---|

| Max Speed | 180 ft/min (55 m/min) |

| Max Throughput | 4,600 SPH (19.7” x 27.8”) |

| Max Sheet Size | 20.8” x 29.5” |

| Min Sheet Size | 12.5” x 11.8” |

| Paper Weight | 115 – 600 gsm |

| Film Compatibility | BOPP (24–42μm), Nylon (24–35μm), PET (20–26μm) |

| Feeder Load Capacity | 25.5” pile |

| Overlap Accuracy | ±0.08” (2 mm) |

| Power Requirements | 3-phase, 400V AC, 9650W |

| Air Requirements | 200 L/min @ 6–8 bar (external compressor) |

| Warm-Up Time | 10 minutes |

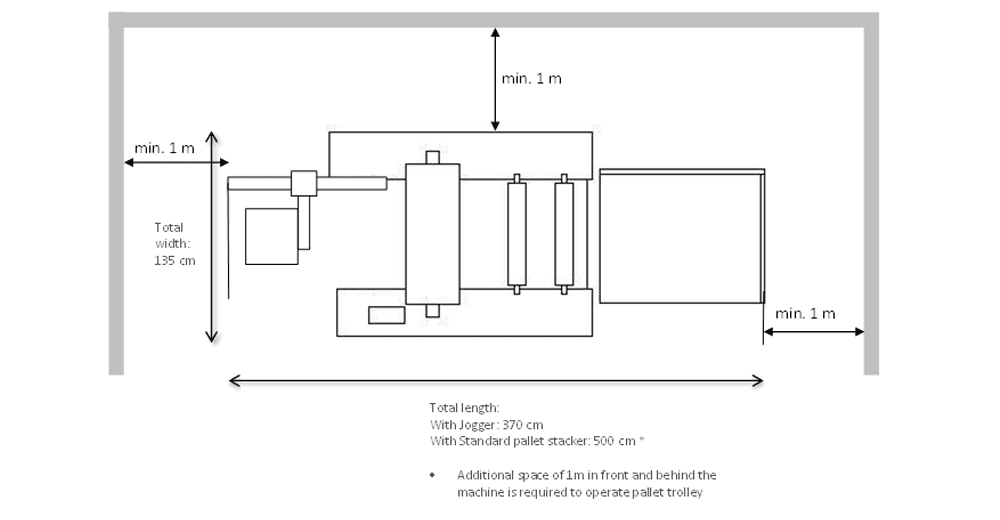

| Machine Dimensions | 53” W x 145.5” L (with jogger) |

| Machine Weight | 1,819 lbs (825 kg) |

Applications

📚 Book Covers & Educational Materials – Durable lamination for publishing and academic printing.

📦 Product Packaging & Inserts – Finishes retail-ready cards, cartons, and inserts.

📄 Commercial Flyers & Mailers – High-speed lamination of brochures, posters, and direct mail pieces.

🛍 Retail Signage & POP Displays – Laminates for in-store displays and promotional graphics.

Available Options

📍 Jogger 530 – Vibrating sheet reception tray (3.9” pile).

📍 Pallet Stacker – Pneumatically controlled lift stacker for 25.5” sheet piles.

📍 Pallet Feeder – Accepts full paper pallets for high-capacity automatic feeding.

📍 Film Loader/Manipulator – Electric lift for 275.5 lb rolls, connected via internal circuit.

📍 Non-Sticky Pressure Roller – Allows lamination of windowed or adhesive-backed sheets.

📍 Additional Film Roll Shaft – Speeds up changeovers during continuous production.

⚠️ Machine must be operated with either a Jogger or Pallet Stacker.

Benefits

✅ Industrial speed and capacity in a space-efficient footprint.

✅ Handles wide film and stock ranges, including thick and coated media.

✅ Fast, intuitive setup and film changes with minimal training required.

✅ Built-in automation and touchscreen interface streamline operator workflow.

✅ Expandable with stacker, feeder, and loader options for full system integration.

Contact Us