Access a layout diagram for this system here

The HDX250 is a heavy-duty combo shrink wrapping system built for industrial applications that demand precision sealing, even airflow, and long-term durability. Combining a rugged L-bar sealer with a powerful MaxAir shrink tunnel, this all-in-one system features a hot knife sealing head, digital temperature controls, and a non-stick mesh tunnel conveyor—making it ideal for mid- to high-volume shrink packaging with a compact footprint and easy mobility.

Key Features

🔷 17" x 21" L-Bar Seal Area – Large sealing zone with cast aluminum seal head and magnetic hold down.

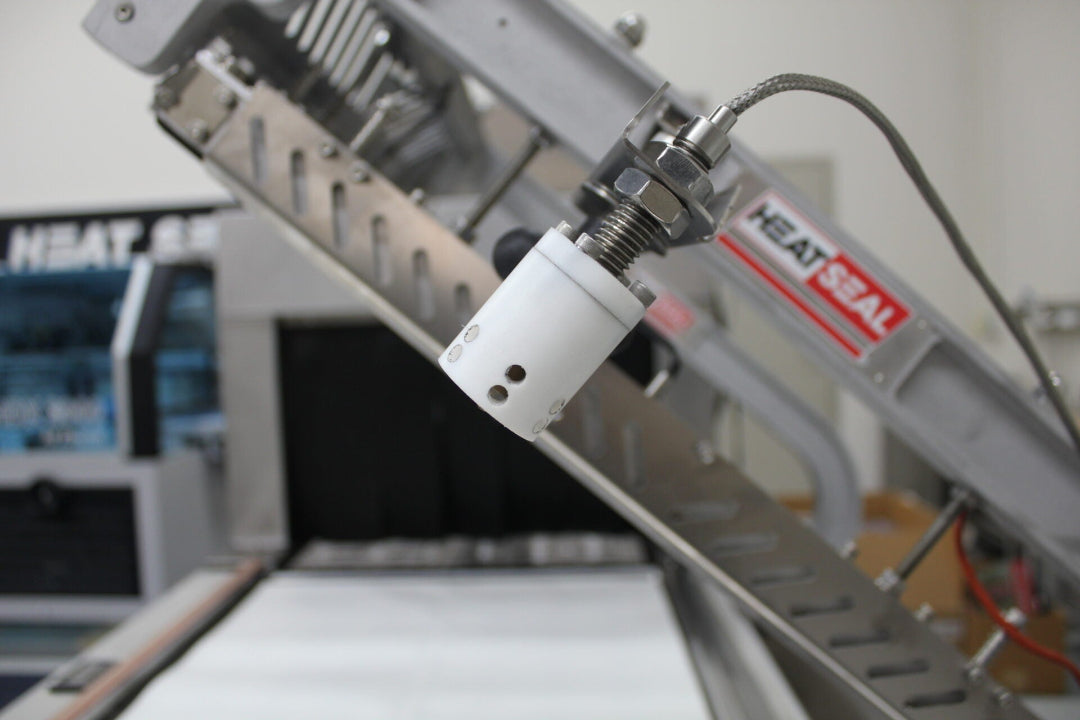

🔷 Hot Knife Exact Seal System – Produces clean, consistent seals with profile customization.

🔷 MaxAir Tunnel Technology – Triples airflow for uniform, 360° shrink wrapping.

🔷 Mesh Tunnel Belt with Riser Bar – Improves bottom shrink and smooth product transfer.

🔷 Auto Tensioning Film Cradle – Keeps film taut for professional-quality results.

🔷 Dual Conveyor Sync – Seal and tunnel conveyors move vertically in tandem for precise package centering.

🔷 Digital Control Panel – Intuitive operation with cycle counter, adjustable temp, and cool-down mode.

🔷 Heavy-Duty Mobility – Casters and levelers included for easy repositioning and stability.

🔷 UL 508A Certified Panel – Built to meet strict electrical safety standards.

Specifications

| Specification | Details |

|---|---|

| Seal Area | 17” W x 21” L (43 x 53 cm) |

| Tunnel Dimensions | 21” L x 16” W x 8” H (53 x 41 x 22 cm) |

| Film Capacity | Up to 22” wide (56 cm) |

| Conveyor Speed | 0–20 ft/min (0–6 m/min) |

| Overall Dimensions | 82” L x 32” W x 59” H (208 x 82 x 150 cm) |

| Working Height | 38” (97 cm) |

| Power Requirements | 220V, 23 Amp, Single Phase |

| Tunnel Wattage | 3,100 W |

| Machine Weight | 800 lbs (363 kg) |

Applications

📦 Industrial Packaging – Handles medium to heavy items like parts kits, tools, and bulk products.

📚 Printed Material Wrapping – Cleanly wraps books, reports, manuals, and presentation folders.

🛍 Retail Product Presentation – Delivers tight, clear shrink wraps for boxed items and gift sets.

🍪 Food & Bakery Packaging – Ideal for trays, prepackaged baked goods, or multipacks.

Available Options

📍 Fully Stainless Steel Construction – For washdown or cleanroom environments.

📍 Tunnel Belt Upgrades – Choose PTFE non-stick mesh or stainless steel wire mesh.

📍 Reverse Tunnel Flow Configuration – Adjust for facility layout or operator flow.

📍 Heated Hole Punch – Ventilation for specific shrink film applications.

📍 Powered Film Unwind – With perforating roller and adjustable inverting head.

📍 Rotary Accumulator Tables – 36” (AT36) or 48” (AT48) for finished package collection.

📍 Gravity Turn Conveyors – GTC180/16 and GTC90/16 for directional change post-wrap.

📍 Spare Parts Kit – Maintenance-ready with part #5820-012.

Benefits

✅ Combines sealing and shrinking into one streamlined unit, reducing footprint and labor.

✅ Delivers even shrink performance using advanced MaxAir airflow design.

✅ Supports a wide range of film types and product sizes.

✅ Built to last with industrial-grade construction and UL-compliant controls.

✅ Modular upgrades available to scale with your growing packaging needs.

Contact Us