Access a layout diagram for this system here

The HDX350 is a premium heavy-duty combo shrink wrap machine, offering an extra-large seal area, enhanced tunnel performance, and expanded power capacity for industrial packaging environments. Featuring a 21” x 25” seal area, MaxAir triple airflow shrink tunnel, and non-stick mesh conveyor, the HDX350 is engineered for demanding applications where speed, consistency, and versatility are paramount.

Key Features

🔷 Large 21” x 25” L-Bar Seal Area – For packaging larger or bulkier products with precision.

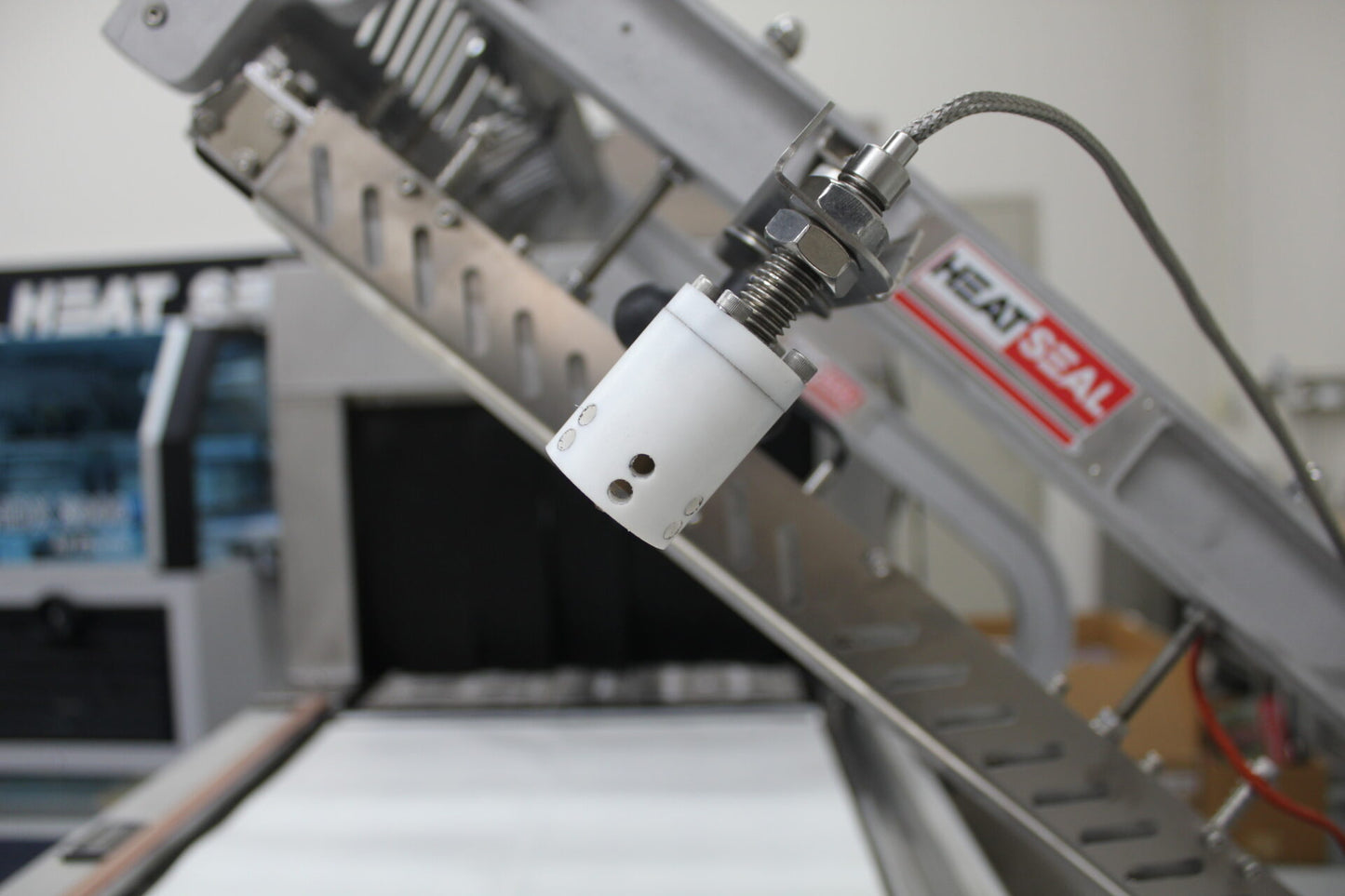

🔷 Hot Knife Exact Seal System – Ensures clean, consistent seals with customizable profile options.

🔷 MaxAir Tunnel with 12” Height – Triple airflow design creates uniform 360° shrink around the product.

🔷 Non-Stick Mesh Conveyor with Riser Bar – Improves bottom shrink and product transfer stability.

🔷 Vertically Synchronized Conveyors – Seal and tunnel conveyors move together for perfect centering.

🔷 Auto Tensioning Film Cradle – Maintains film tightness for professional wrap quality.

🔷 Digital UL-508A Certified Control Panel – Easy operation, cycle counter, precise temp control, and safety alerts.

🔷 Tunnel Slide Adjustment – Quick horizontal repositioning for maintenance or product clearance.

🔷 Two-Year Warranty – Industrial reliability backed by strong manufacturer support.

Specifications

| Specification | Details |

|---|---|

| Seal Area | 21” W x 25” L (53 x 64 cm) |

| Inside Tunnel Size | 27” L x 20” W x 12” H (69 x 51 x 30.5 cm) |

| Film Capacity | 25” W (64 cm) |

| Tunnel Conveyor Speed | 0–20 ft/min (0–6 m/min) |

| Power Requirements | 220V, 48 Amp, Single Phase |

| Tunnel Wattage | 6,200 W |

| Working Height | 38” (97 cm) |

| Machine Dimensions | 95” L x 35” W x 63” H |

| (43” W w/ tunnel extended) | |

| Machine Weight | 1,080 lbs (490 kg) |

Applications

📚 Book & Media Wrapping – Shrinks around books, binders, reports, and boxed sets.

📦 Industrial & Manufacturing – Durable enough for tool kits, mechanical parts, and bulk hardware.

🛍 Retail Multipacks – Clean, professional presentation for gift boxes, games, or multi-unit products.

🍪 Food Packaging – Ideal for prepackaged trays, baked goods, and shelf-ready packs.

Available Options

📍 Fully Stainless Steel Construction – For cleanroom or washdown environments.

📍 Reverse Flow Configuration – Reverses tunnel direction to fit your workspace.

📍 Powered Conveyor Lift – Raises/lower conveyors for access or cleaning.

📍 Air-Actuated Sealing Head – For enhanced sealing force and speed.

📍 Heated Hole Punch – Adds venting to prevent ballooning inside film.

📍 Tunnel Belt Options – Choose PTFE non-stick mesh or stainless wire mesh.

📍 Powered Film Unwind System – With perforating roller and adjustable inverting head.

📍 Turn Conveyors (GTC90/22 & GTC180/22) – 90° and 180° turn options for downstream flow.

📍 Rotary Accumulator Tables (AT36, AT48) – Collect and stage finished packages.

📍 Spare Parts Kit (#5820-020) – For proactive maintenance and minimal downtime.

Benefits

✅ Supports larger and heavier products than standard shrink combo systems.

✅ Delivers consistent shrink quality with advanced airflow and film tensioning.

✅ Reduces film waste and rewraps with precise centering and heat control.

✅ Configurable and expandable, making it ideal for growing production needs.

✅ Reliable and safe, with UL-certified controls and two-year warranty support.

Contact Us