B1 Pallet-Feed Folder

Intelligent automation for ultimate usability. The Horizon AFC-746F B1 Pallet-Feed Folder adds efficiency to the folding process.

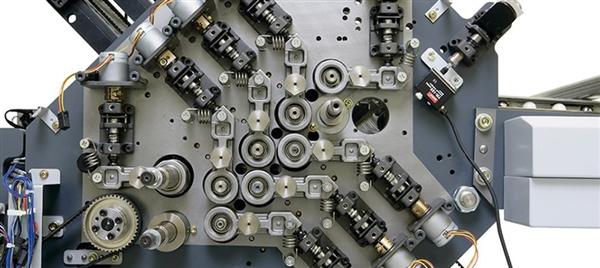

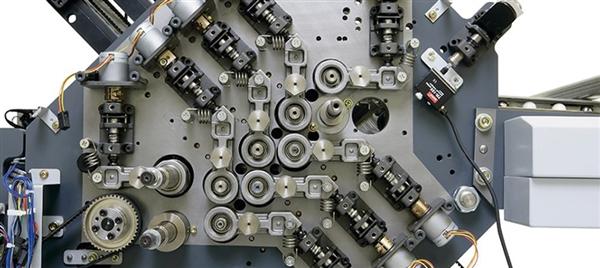

The Horizon AFC-746F B1 PFF boasts advanced setup automation and a user-friendly 10.4" color touch-screen control panel, making it easy to select from a variety of commonly used fold formats and sheet sizes. With 45 automated adjustments, including in-feed, roller gap, buckle fold, and knife-fold sections, the AFC-746F offers quick changeover and fully automated setup. Equipped with 6 buckle plates and a 1st knife plus 2 buckles under the knife, as well as a standard buckle and 2nd knife, this folder can handle a wide range of fold patterns while maintaining a smaller footprint than traditional console folders.

Computerized Suction Feed Cross Folder

It handles sheet sizes up to 29.1” x 43.3” and as small as 8.3” x 8.3” with programmable memory for up to 200 different jobs. It includes pile feeder with suction head and has an optional pallet or continuous feeder for maximum application flexibility. Sheet sizes up to 51” long can be fed with the continuous feeder.

The AFC-746F has a new ergonomically friendly slitter shaft removal system, where the operator can remove the perforation shaft automatically for easier blade setting – a quick release lever, internal elevator, and slide out carriage highlight this new feature. A new power stop system, where the transport belt at the knife section selectively slows/stops as the sheet reaches the knife stopper, eliminates bounce-back and damage to the sheet.

Horizon AFC-746F B1 Pallet-Feed Folder Features

- The folder is easy and intuitive to set-up, even without a skilled operator, thanks to the intelligent automation and user-friendly design.

- 20 fold patterns are automatically set by inputting the sheet size and selecting a fold pattern through the large color touchscreen.

- Equipped with 6 buckles, 1 cross knife and 2 buckles below the knife to support a wide variety of fold patterns.

- 3 different types of feed units can be selected for various work environments: Flat Pile Feeder, Pallet Pile Feeder and Round Pile Feeder.

- High-speed production of 36,000 sheets/hr. (A4 - Parallel Fold) or 11,000 sheets/hr. (625W x 880L mm / 24.6” x 34.6” - 16-page Cross Fold).

- Fold rollers are constructed with a combination of steel and soft polyurethane for superior grip and sharp, consistent folding.

- The AFC-746S/746D can be enhanced with JDF workflow from upstream to the postpress using pXnet bindery control system.

Horizon AFC-746F B1 Pallet-Feed Folder Specifications

- Up to 42,000 Sheets/hr.

- Sheet sizes up to 29" x 51"

- 20 Pre-set Fold Patterns

- 6 Fold Plates

- User Friendliness

- Advanced Automation

- JDF Workflow Compatibility

- Color LCD Touchscreen

- Buckle Fold

- Knife Fold

- Perforation

- Folding Rollers

- Delivery Conveyor

- Sheet Transportation

- Suction Head

- Feed Rotor

Horizon AFC-746F B1 Pallet-Feed Folder Details

| Machine Structure | 6KTTL (6 Buckles + 1st Fold Knife + 2 Buckles below Knife*1 + 2nd Fold Knife) | ||

| Sheet Size | w/ Flat Pile Feeder | 738(W) x 1,100(L) mm (29.055” x 43.310”) | |

| 210(W) x 210(L) mm (8.270” x 8.270”) | |||

| w/ Pallet Pile Feeder | 738(W) x 1,100(L) mm (29.055” x 43.310”) | ||

| 210(W) x 297(L) mm (8.270” x 11.695”) | |||

| w/ Round Pile Feeder | 738(W) x 1,300(L) mm (29.055” x 51.180”) | ||

| 210(W) x 148(L) mm (8.270” x 5.830”) | |||

| Sheet Weight Range | 35 to 220 gsm | ||

| Art/Coated Paper 50 to 232 gsm | |||

| Knife Fold Size | 1st Knife | Max. 738(W) x 550(L) mm (29.0” x 21.6”) | |

| Min. 160(W) x 100(L) mm (6.3” x 4.0”) | |||

| 2nd Knife | Max. 550(W) x 360(L) mm (21.6” x 14.1”) | ||

| Min. 160(W) x 100(L) mm (6.3” x 4.0”) | |||

| Max. Pile Height | w/ Flat Pile Feeder | 750 mm (29.5”) [within 600 kg (1,323 lb)] | |

| w/ Pallet Pile Feeder | 1,200 mm (47.2”) (pallet included) (Min. height of pallet is 120 mm / 4.8”) [within 1,000 kg (2,205 lb)] |

||

| Belt Speed | 30 to 230 m (99 to 754 ft )/min. [Knife Fold : 180 m (590 ft )/min.] | ||

| Production Speed | 36,000 sheets/hr. [A4 (8.5” x 11”) Parallel Fold] | ||

| w/ Flat Pile Feeder | 750 mm (29.5”) [within 600 kg (1,323 lb)] | ||

| w/ Pallet Pile Feeder | 1,200 mm (47.2”) (pallet included) (Min. height of pallet is 120 mm / 4.8”) [within 1,000 kg (2,205 lb)] |

||

| Standard Fold Roller | Combination of Soft Polyurethane Foam Rubber and Steel Roller | ||

| Roller Gap Adjustment | Insert the instructed number of sheets into the gap adjust lever. | ||

| Automatic Setup | Side Lay Guide, Feed Table Guide, 1st to 6th Buckles, K2 Buckle, 1st and 2nd Knife Stoppers | ||

| Fold Patterns | Parallel Fold, Short Fold, Open Gate Fold, Accordion Fold, Zigzag (4 panel) Fold, Zigzag (5 panel), Fold, Zigzag (6 panel) Fold, Zigzag (7 panel) Fold, Letter Fold, Roll Fold, Double Parallel Fold, 8-page Cross Fold, 12-page Transformation Fold, 12-page Cross Fold, 16-page Transformation Fold (1), 16-page Cross Fold, 16-page Transformation Fold (2), 24-page Cross Fold, DL Fold (Letter), DL Fold (Accordion) | ||

| Job Memory | 200 Jobs | ||

| Voltage/Frequency | 3-Phase 200/220/400V, 50/60Hz | ||

AFC-746F B1 Optional Accessories

| Horizon AFC-746F B1 Pallet-Feed Folder Accessories | |

| Gluing Unit CGU-50 | The gluing unit can produce 8-page or 12-page glued booklets. |

|

Gate Fold Buckle: GFB-74 |

The gate fold buckle can be setup quickly, with no special skills for precise, accurate closed-gate folding. |

| Supersonic Detector : USS-74 | Optional supersonic detector is available for double feed detection.This detects space between sheets for accurate double feed detection even with a solid black printed sheet. |

| Front Perforation Unit : FP-74 (FSP-74) | This unit permits perforating before folding. An accurate blade drum provides for high-precision micro perforation. Skip perforation unit (FSP-74) is also available. |

| Strip Trim Device : AF-ST6 | Strip trimming after the parallel fold section can be performed using slitters for multiple-up jobs. Stripped width can be adjusted. (3 mm to 10 mm at 1 mm intervals) |

| Strip Trim Device below 1st Knife : KT-ST6 | Strip trimming in the cross fold section can be performed using slitters for multiple-up jobs. Stripped width can be adjusted. (3 mm to 10 mm at 1 mm intervals) |

| Edgte Trim Device Below 1st Knife: KT-ET6 | Segmented rollers below the 1st knife are provided as standard parts. Simply attach the KT-ET6 to trim the open/closed side of glued signatures to complete the booklet (8-page, 12-page). |

| Blades | A wide variety of optional blades are available for various applications. |

| Mobile Knife Fold Unit: MKU-54 |

|

| Mobile Knife Fold Unit: MKU-54T |

|

| Press Stacker: PST-40 |

|

| Press Stacker with Pile Delivery: PSX-56 |

|

Contact Us