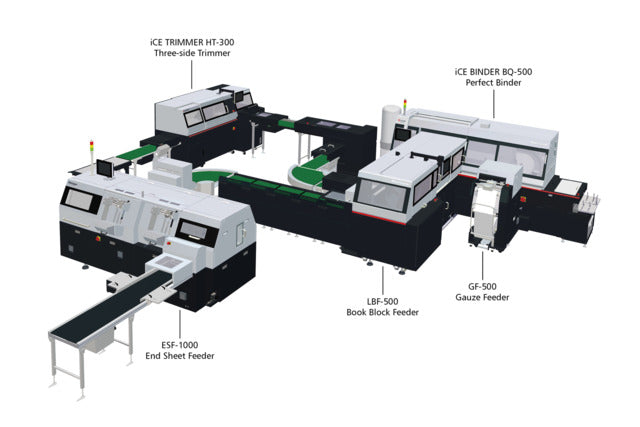

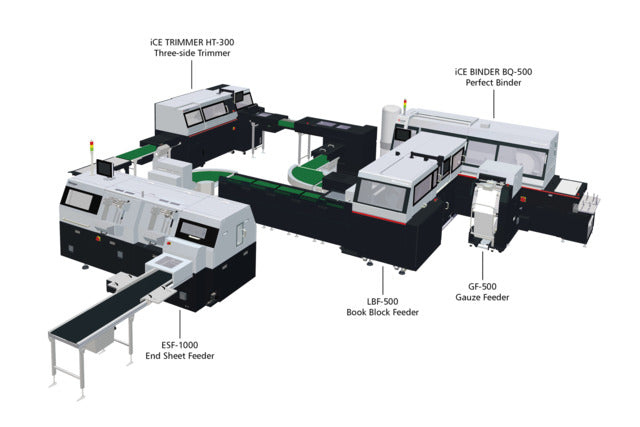

Horizon ESF-1000 End Sheet Feeder

Enhance your case binding workflow with the Horizon ESF-1000 End Sheet Feeder. Purpose-built to apply folded end sheets to book blocks, the ESF-1000 automates a critical step in the creation of premium case-bound books. Compatible with a wide range of binding formats and fully integrable with Horizon’s BQ-500, this high-performance unit ensures precision, flexibility, and unmatched productivity.

Key Features

🔷Adjustable Tipping Position — Attach end sheets up to 6 mm from the spine, adjustable by milling depth.

🔷Versatile Compatibility — Works with loose sheets, folded signatures, glued, or sewn book blocks.

🔷Built-In Thickness Caliper — Automatically adjusts for variable book thicknesses.

🔷Barcode Integration Ready — Optional readers and printers ensure correct matching during casing-in.

🔷Dual-Side Tipping — Tip one or two end sheets on the front and/or back of each book block.

🔷Inline or Offline Use — Operates independently or inline with the Horizon BQ-500 binder.

Specifications

| Specification | Detail |

|---|---|

| Max Cycle Speed (bound) | Up to 1,000 cycles/hour |

| Max Cycle Speed (loose) | Up to 800 cycles/hour |

| Book Block Types | Loose sheet, signature, glued, or sewn |

| End Sheet Options | 1 or 2 (front and/or back) |

| Inline Integration | Horizon BQ-500 binder |

| Thickness Detection | Automatic via caliper |

| Machine Dimensions (W×D×H) | 115.35″ × 49.57″ × 76.06″ |

| Glue Type | Hot melt (with optional PM-ESF melter) |

Applications

Benefits

Contact Us