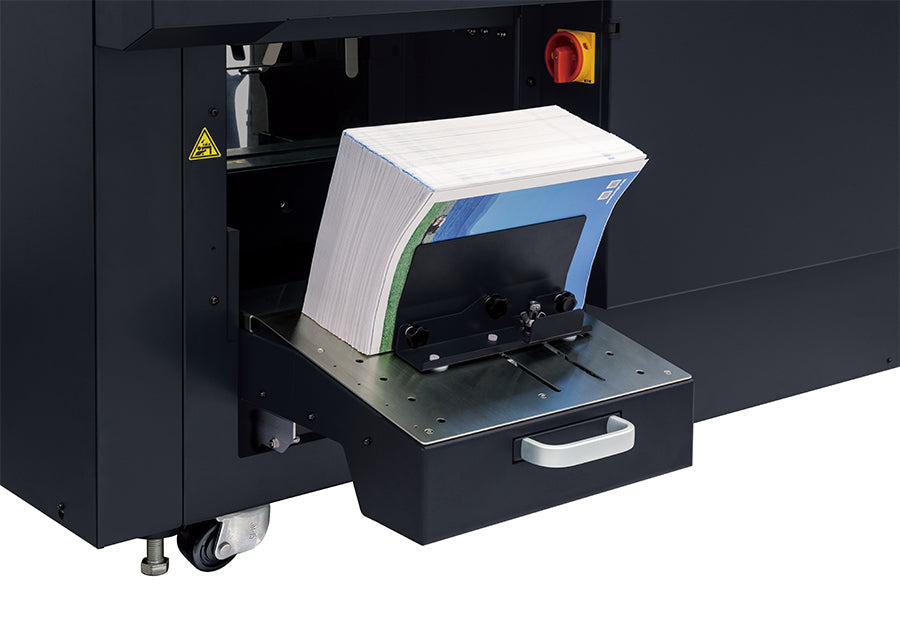

Automated Perfect Binder

BQ-300 — compact, next-gen perfect binder for digital, short-run, and book-of-one production.

The BQ-300 delivers efficient, high-quality book production at up to 500 books/hour. A 15" touchscreen enables automated setup, variable thickness detection, and reusable templates. Built for digital workflows, it supports EVA hot melt and connects seamlessly with inline trimmers and robotic automation for scalable throughput.

Key Features

- Binds up to 2" (51 mm) at up to 500 cycles/hour

- Automated setup with variable thickness detection

- 15" Horizon XUI touchscreen with 999-job memory

- Rotary suction cover feeder with precision scoring

- Dual gluing rollers, side gluing, and integrated nipping

- Expandable with inline trimmers, robotics, and iCE LiNK

Benefits

- Ideal for short runs, variable data, and book-of-one

- Crisp spines and clean hinges via automated scoring

- Template-driven setup reduces operator training needs

- Scales with barcode matching, robotics, inline finishing

- Dust containment and fume extraction for clean operation

Applications

- 📄 On-demand perfect binding for digital short runs

- 📚 Softcover books, manuals, catalogs

- 📦 Print-on-demand and book-of-one workflows

- 🛍 Premium photo books and thick publications

Available Options

Specifications

| Specification | Detail |

|---|---|

| Book Block Size (Max) | 12.59" × 12.59" (320 × 320 mm) |

| Book Block Size (Min) | 5.32" × 4.14" (135 × 105 mm) |

| Book Thickness Range | 1–51 mm (0.04"–2.00") |

| Cover Size (Max) | 12.59" × 25.98" (320 × 660 mm) |

| Cover Size (Min) | 5.32" × 8.86" (135 × 225 mm) |

| Cover Weight Range | 81.4–302.4 gsm (normal), 104.7–348.9 gsm (coated) |

| Max Production Speed | 500 cycles/hour |

| Glue Type | EVA hot melt (120–190 °C) |

| Milling Depth | Up to 4 mm (0.5 mm steps) |

| Power | 3-phase, 200–400 V, 50/60 Hz (transformer may be required) |

| Dimensions (W × D × H) | 91.8" × 35.8" × 60.2" (2,330 × 910 × 1,530 mm) |

| Weight | 2,138 lb (970 kg) |

Specifications subject to change without notice.

Contact Us