Automated Hybrid Binding System for Offset and Digital Workflows

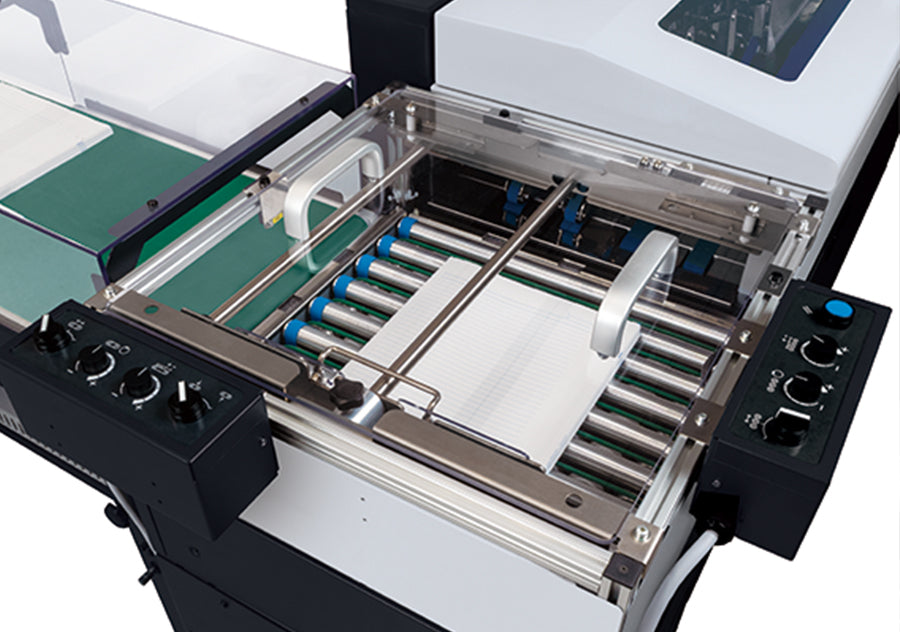

The Horizon MiniCABS is a compact, computer-automated bookbinding system designed for short to medium production runs. Built to streamline binding from gathering through three-side trimming, the MiniCABS supports both offset and digital workflows with seamless integration and superior automation.

Key Features:

🔷 Compact layout with full inline automation from gathering to trimming

🔷 Hybrid configuration supports both offset signatures and digital output

🔷 Handles book blocks from loose sheets, sewn blocks, or glue-tacked sets

🔷 Scalable design integrates with Horizon BQ-500 binder and HT-series trimmers

Specifications Table:

| Feature | Details |

|---|---|

| Max Book Size | 320 x 320 mm (12.59" x 12.59") |

| Min Book Size | 148 x 105 mm (5.83" x 4.14") |

| Max Book Block Thickness | 65 mm (2.56") |

| Compatible Binder | BQ-500 EVA or PUR |

| Trimmer Options | HT-80, HT-300, HT-1000V |

| Max Speed (Gathering Only) | 2,000 cycles/hour |

| Max Speed (System Mode) | 800 cycles/hour |

| Voltage | 200–240V Single Phase |

| Glue Types | EVA, PUR (optional tank) |

Applications:

📚 Softcover bookbinding

📖 Digital print-on-demand finishing

🖨️ Short-run offset production

🏫 School yearbooks, catalogs, manuals

Available Options:

📌 Multiple gatherer modules (MG-600)

📌 End sheet and gauze feeders (ESF-1000, GF-500)

📌 Choice of trimmer models for size/volume flexibility

📌 Image checkers, reject units, buffer conveyors, and hand-feed options

Benefits:

✅ Labor-saving automation reduces operator training and costs

✅ Small footprint supports compact finishing environments

✅ High-end quality and repeatability for both short runs and larger jobs

✅ Fully scalable with Horizon ecosystem

Contact Us