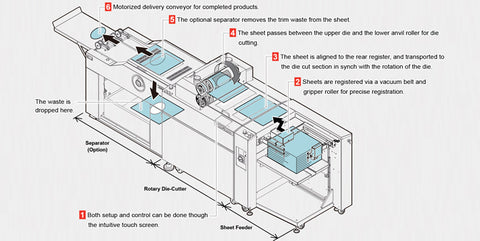

The Horizon RD-N4055 is a high-speed rotary die-cutting system designed for short-run and on-demand finishing applications. This machine integrates die-cutting, waste separation, and stacking into a single-pass workflow, significantly reducing manual labor and increasing productivity. Featuring repeat register technology, the RD-N4055 allows for multiple-up applications using a single die, minimizing tooling costs while ensuring precise, high-quality cuts.

Read a case study on this system here!

With automated feeding, servo-driven gripper rollers, and a vacuum belt transport system, this die-cutter delivers consistent alignment and accuracy, making it ideal for business cards, greeting cards, labels, folding cartons, and more.

Key Features

🔷 Automated Die-Cutting Workflow – Die-cuts, separates waste, and stacks finished products in one pass.

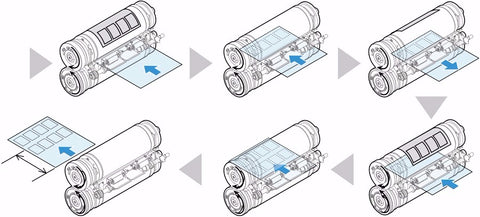

🔷 Repeat Register Technology – Enables up to 8 repeats per sheet, reducing die costs for multi-up applications.

🔷 High-Speed Production – Processes up to 6,000 sheets per hour, handling 126,000 business cards per hour in a 21-up layout.

🔷 Vacuum Belt Feeding System – Provides stable and accurate sheet feeding to prevent misfeeds.

🔷 Creasing & Kiss-Cutting Capability – Supports creasing, perforating, and kiss-cutting for stickers, labels, and folding cartons.

🔷 Servo Motor-Driven Gripper Rollers – Ensures precise die-cut registration without affecting processing speed.

🔷 Intuitive Touchscreen Interface – Simplifies operation with graphical setup guides and automated settings.

🔷 Flexible Delivery & Stacking Options – Configurable with conveyor, card stacker, or sheet stacker for different workflow needs.

🔷 Automated Waste Removal – Integrated separator system removes excess material, ensuring clean product output.

Specifications

| Specification | RD-N4055 Details |

|---|---|

| Max Sheet Size | 15.7” x 21.6” (400 x 550 mm) |

| Min Sheet Size | 7.8” x 10.8” (200 x 275 mm) |

| Processed Media | Normal paper, coated paper, cardboard |

| Material Thickness | 127.9 – 400 gsm |

| Max Die-Cutting Thickness | 0.5 mm (0.019”) (blade height 0.8mm) |

| Creasing Thickness | Max 0.4 mm (0.015”) |

| Max Speed | 6,000 cycles per hour |

| Feeder Stack Height | Up to 19.68” (500mm) |

| Power Supply | 200-240V, 50/60Hz |

| Machine Dimensions | 136.7” x 32.3” x 47.1” |

| Weight | 2,414 lbs (1,095 kg) |

Applications

✅ Business Card & Greeting Card Production – High-speed, multi-up cutting for business and greeting cards.

✅ Packaging & Folding Cartons – Produces custom-shaped boxes, pocket folders, and specialty packaging.

✅ Label & Sticker Production – Handles kiss-cutting and perforating for roll labels, stickers, and decals.

✅ On-Demand Print Finishing – Ideal for short-run, custom-cut print applications.

Available Options

🔹 SPC-N4055 Separator – Removes waste automatically for clean product output.

🔹 CSD-40RD Card Stacker – Stacks die-cut products up to 40mm high for efficient handling.

🔹 FFU-N4055 Sheet Feeder – Automated sheet feeding for continuous production.

🔹 BR-N4055 Code Reader – Enables job separation using barcodes for batch production.

🔹 MS-3346 Mark Sensor – Auto-corrects print shift for perfect die-cut registration.

Benefits

-

Maximizes production efficiency with an all-in-one die-cutting, separation, and stacking solution.

-

Reduces tooling costs with Repeat Register Technology, allowing multi-up applications from a single die.

-

Delivers high-precision cuts with servo motor-driven gripper rollers for perfect alignment.

-

Versatile finishing applications for business cards, labels, folding cartons, and promotional materials.

-

Reduces manual labor with an automated waste separation and stacking system.

RD-4055 Diagrams

Contact Us