Dual Magnetic Cylinder Rotary Die-Cutting System

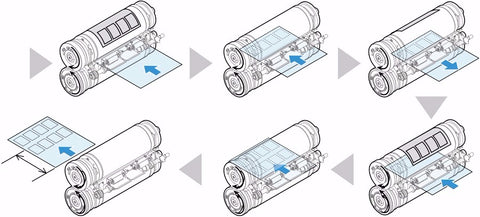

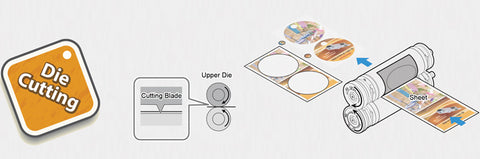

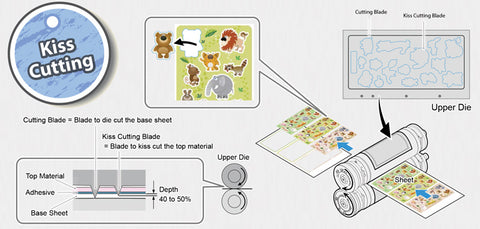

The Horizon RD-N4055DMC is an advanced dual magnetic cylinder rotary die-cutting system designed for short-run and variable print finishing. It enables single-pass or multi-pass production with two cylinders, providing greater flexibility, precision, and cost efficiency for complex die-cutting, creasing, and kiss-cutting applications.

Key Features

🔷Dual magnetic cylinder system — Supports single-pass and multi-pass workflows for maximum flexibility.

🔷Repeat Register — Up to 8 repeats per sheet reduces die costs on multi-up layouts.

🔷Multi-depth cutting — Cuts at two depths per pass for creasing, perforating, and kiss-cutting simultaneously.

🔷High-speed throughput — Processes 6,000 sheets/hour or 126,000 business cards/hour (21-up).

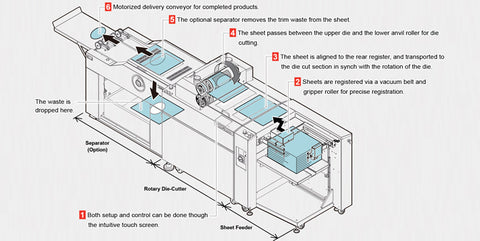

🔷Vacuum belt feeding — Stable, accurate sheet control that minimizes misfeeds.

🔷Servo-driven gripper rollers — Precise registration ensures consistent output.

🔷Touchscreen GUI — Fast setup and real-time adjustment control.

🔷Automated waste removal — Integrated separator delivers clean, finished pieces.

🔷Flexible delivery — Compatible with conveyor, card stacker, or sheet stacker systems.

Specifications

| Specification | RD-N4055DMC Details |

|---|---|

| Max Sheet Size | 15.7″ × 21.6″ (400 × 550 mm) |

| Min Sheet Size | 7.8″ × 10.8″ (200 × 275 mm) |

| Processed Media | Normal paper, coated paper, cardboard |

| Material Thickness | 127.9–400 gsm |

| Max Die-Cutting Thickness | 0.5 mm (0.019″) — blade height 0.8 mm |

| Creasing Thickness | Max 0.3 mm (0.011″) |

| Max Speed | 6,000 cycles/hour |

| Feeder Stack Height | Up to 19.68″ (500 mm) |

| Power Supply | 200–240 V, 50/60 Hz |

| Machine Dimensions | 136.7″ × 32.3″ × 47.1″ |

| Weight | 2,568 lb (1,165 kg) |

Applications

Additional Benefits Over RD-N4055

Case Study

System Diagrams

Process Examples

Contact Us