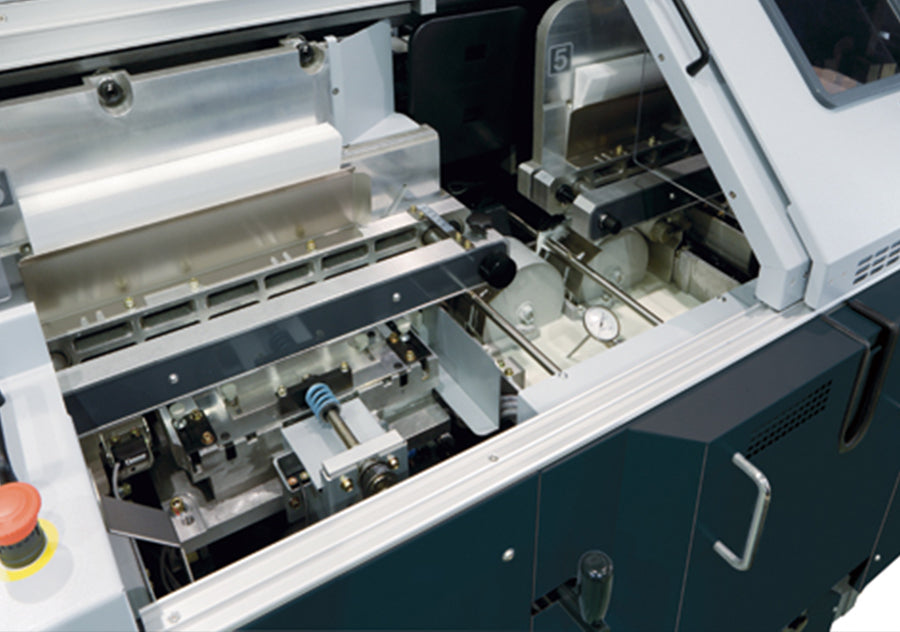

The Horizon SB-09V and SB-09VF are fully automated, high-performance perfect binders designed for efficient, high-quality book production. These 9-clamp binding systems are capable of processing up to 4,000 books per hour, making them ideal for short to long production runs. With automated setup, advanced quality control, and flexible glue application, these binders deliver consistent, durable binding results. Both models support EVA and PUR hotmelt adhesives, offering strong, lay-flat binding for coated and uncoated stock.

The SB-09V features a roller grip-style cover feeder, while the SB-09VF adds a rotary grip-style cover feeder, which is optimized for handling flap covers. Both models integrate seamlessly with Horizon’s bindery automation system (pXnet) for efficient workflow management and JDF compatibility.

Key Features

🔷 High-Speed Production – Capable of binding up to 4,000 books per hour.

🔷 Fully Automated Setup – Reduces manual adjustments, increasing efficiency and accuracy.

🔷 Flexible Cover Feeding – SB-09V uses a roller grip feeder, while SB-09VF adds a rotary grip feeder for flap covers.

🔷 EVA & PUR Compatibility – Interchangeable melt tanks allow for EVA and PUR hotmelt glue applications.

🔷 Superior Glue Penetration – Dual application rollers ensure deep glue penetration for strong, durable binds.

🔷 Advanced Nipping System – Provides high-pressure nipping for a clean, professional spine finish.

🔷 Precision Cover Scoring – Automatically adjusts to book thickness, allowing for up to 4 score lines.

🔷 Automatic Thickness Detection – The TD-600 unit (optional) ensures precise thickness measurement for quality control.

🔷 Quality Assurance Features – Optional weight checking, image checking, and rejecting units prevent errors and ensure consistent quality.

🔷 pXnet Bindery Integration – Supports JDF workflow automation for seamless production management.

Specifications

| Specification | SB-09V / SB-09VF Details |

|---|---|

| Number of Clamps | 9 |

| Max Binding Speed | 4,000 books per hour |

| Binding Type | With/without milling, pad binding |

| Book Block Thickness | 1 – 45 mm (0.04” – 1.77”) |

| Max Cover Size | 400 x 660 mm (15.7” x 25.9”) |

| Min Cover Size | 135 x 220 mm (5.4” x 8.7”) |

| Cover Weight | 82 – 302 gsm (normal) / 105 – 348 gsm (coated) |

| Cover Feeder Options | Roller grip (SB-09V) / Rotary grip (SB-09VF) |

| Glue Type | EVA / PUR hotmelt (interchangeable tanks) |

| Production Speed | 4,000 books per hour |

| Power Requirements | 3-Phase 200 / 208 / 400V, 50/60Hz |

| Machine Dimensions | SB-09V: 4,720 x 1,685 x 1,660 mm (system configuration) |

Applications

✅ Perfect Binding – High-speed book production for publishing, commercial printing, and digital printing

✅ Lay-Flat Binding – Ideal for coated stocks and high-quality print materials using PUR glue

✅ On-Demand Printing – Compatible with short-run, medium-run, and high-volume book production

✅ Variable Book Sizes – Handles a wide range of book sizes and thicknesses with automated adjustments

✅ Automated Bindery Workflows – JDF-ready for seamless workflow automation and job tracking

Available Options

🔹 Rotary Grip Cover Feeder (SB-09VF) – Optimized for flap cover applications

🔹 Weight Checking & Rejecting Units (WD-17 / RU-17) – Ensures quality control by detecting missing covers or signatures

🔹 Book Block Feeder (BBF-SB) – Automates the feeding of sewn or pre-glued book blocks

🔹 pXnet Bindery System – Integrates with JDF workflows for centralized production management

🔹 Cooling Conveyor Options – Custom configurations for PUR-bound book cooling

Benefits

- Maximizes production speed while maintaining high-quality binding

- Reduces setup time with fully automated adjustments

- Increases glue penetration for stronger, more durable book binding

- Ensures quality control with optional image checking, weight checking, and thickness detection

- Flexible binding solutions for short-run, medium-run, and large-scale production

Contact Us