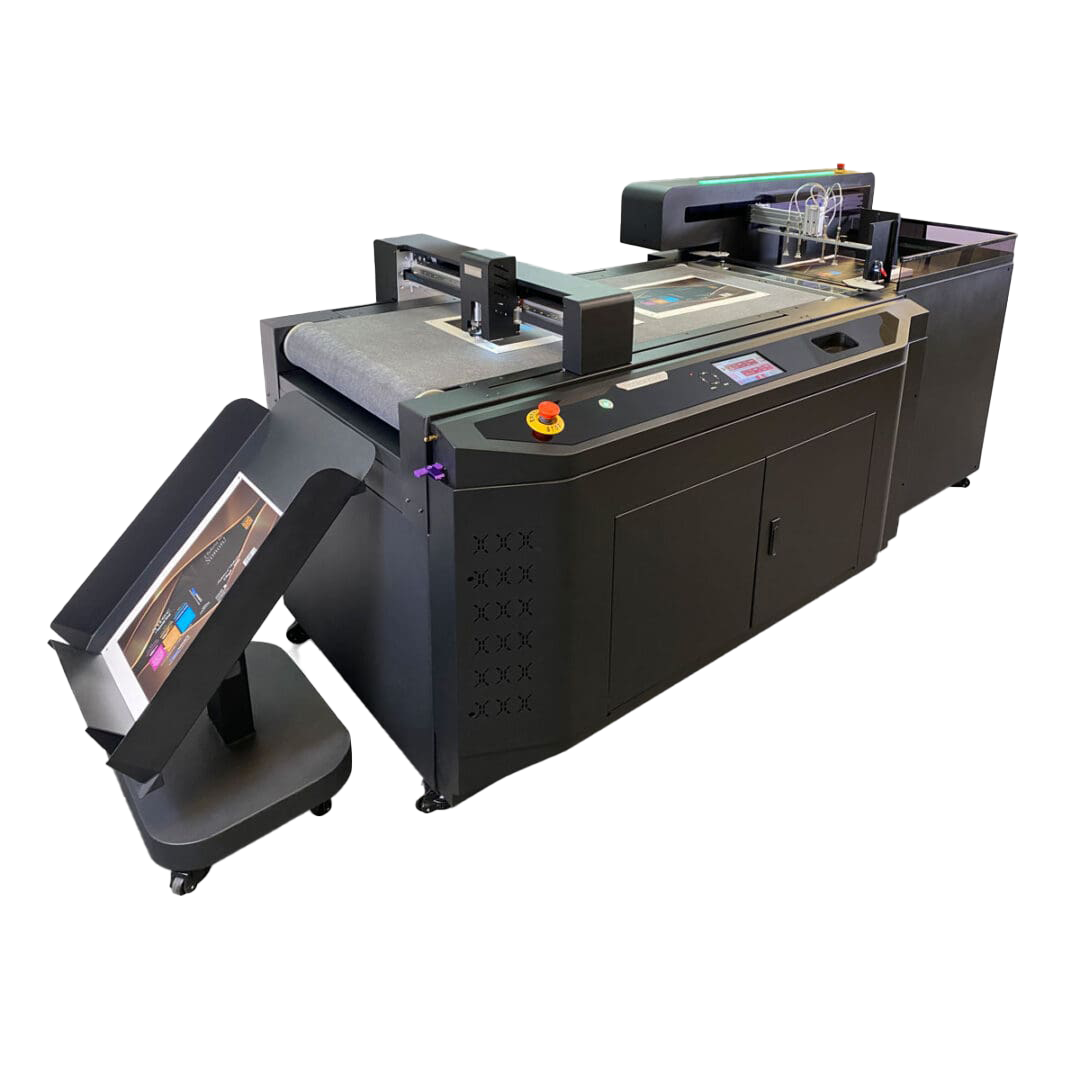

Fully automated sheet-fed flatbed cutter/creaser with advanced tangential creasing technology, QR-code driven workflow, and unattended production capability.

Key Features

🔷 Fully Automated Operation – Auto sheet feeding with advanced separation and pre-placement for continuous unattended cutting and creasing.

🔷 Dual Tool Head – Tangential creasing wheel (up to 2.5 kg force) and contour cutting blade (up to 1.3 kg force) operate simultaneously for faster throughput.

🔷 Smart Registration – Vision3 CCD camera with SmartMark and patented rear-mark scanning system ensures perfect registration and back-side creasing.

🔷 Lightning Fast – Up to 1,200 mm/sec cutting speed with selectable fast, standard, and high-quality modes.

🔷 QR-Code Driven Workflow – Automatic job recognition and retrieval with ColorCut Pro 5 software for batch and mixed job production.

Specifications

| Category | Details |

|---|---|

| Cut Area (Auto Feed) | 483 × 700 mm |

| Cut Area (Manual) | 495 × 735 mm |

| Max Media Size | 500 × 720 mm (auto), 550 × 850 mm (manual) |

| Media Thickness | Paper/card up to 800 micron (max depth 1000 micron for low-density substrates) |

| Hold-Down | 2-zone vacuum bed, 750 W vacuum pump |

| Tools | Tangential creasing wheel (3 widths), passive blade holder, pen holder |

| Creasing Pressure | Up to 2.5 kg |

| Cutting Force | Up to 1.3 kg |

| Speed | Fast: 1,200 mm/s, Standard: 960 mm/s, High Quality: 750 mm/s |

| Feeder Capacity | Up to 25 kg / 2,000 sheets |

| Power (Cutter) | 220–240 V / 6.8 A / 700 W |

| Power (Vacuum Pump) | 220–240 V / 4.5 A / 750 W |

| Dimensions (Cutter) | 1,705 × 1,095 × 1,120 mm, 236 kg |

| Dimensions (Feeder) | 895 × 1,000 × 1,225 mm, 142 kg |

Applications

📦 Packaging & Folding Cartons

🏷️ Labels & Stickers

🛍️ Point-of-Sale Displays

🎨 Prototypes & Short-Run Custom Designs

Available Options

📌 Tangential Creasing Wheels – Narrow (0.28 mm), Medium (0.55 mm), Wide (0.95 mm)

📌 Passive Drag Blade Holder – For contour cutting

📌 ColorCut Pro Server Station – Dedicated PC & job server for automated workflows

📌 Replacement Cutting Mats & Blades – Multiple blade angles for label, card, and rigid media cutting

Benefits

✅ Unattended Productivity – Automatic loading, separation, and pre-placement saves labor time.

✅ Superior Crease Quality – Tangential technology creates deeper, more defined creases.

✅ Error-Free Job Recall – QR-code file retrieval eliminates operator mistakes.

✅ Flexible Workflow – DIRECT (PC-connected) or HELD (stand-alone) job modes.

✅ Compact & Ergonomic – Pivoting 7″ touchscreen and modular catch tray fit in busy production environments.

Contact Us