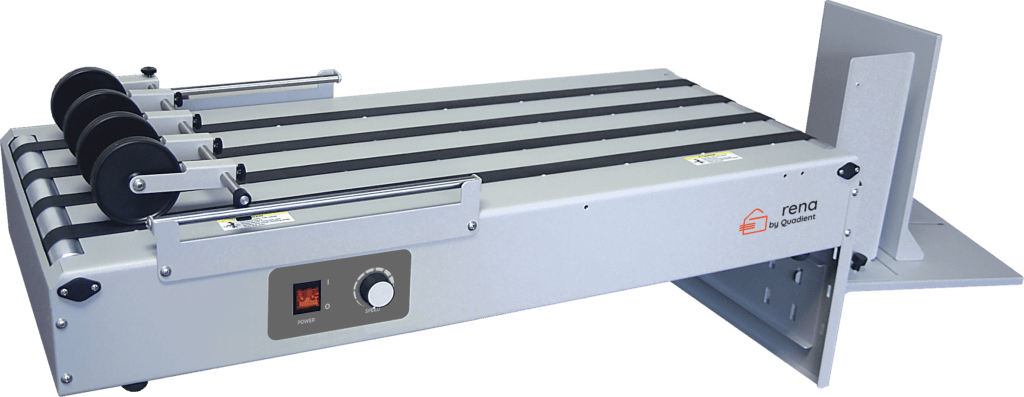

Three-Foot Variable Speed Tabletop Conveyor

The RENA TB-390 is a compact, high-performance tabletop mail conveyor designed to move materials smoothly from your printer or tabber to stacking or drying stations. With variable speed control, integrated drop stacker, and support for optional infrared drying, the TB-390 is built for efficiency and flexibility in modern mail production environments. Its lightweight footprint and compatibility with other RENA systems make it a great addition to any mailroom.

Key Features

🔷 Variable Speed Control – Adjusts speed up to 120 feet per minute for smooth integration into workflows

🔷 Built-In Drop Stacker – Provides clean, organized stacking for finished pieces

🔷 Optional IR Dryer – Enhances performance with fast drying for printed materials

🔷 Compact Tabletop Design – Fits easily into small or space-constrained workstations

🔷 Cross-Stacking Model Available – ‘S’ model adds cross-stack guides and dryer integration

🔷 Safety Equipped – Includes pinch guards and motor stall detection for operator protection

Specifications

| Specification | Details |

|---|---|

| Conveyor Length | 3 feet |

| Speed | 0–120 feet per minute (variable) |

| Material Size (Min) | 3” x 5” |

| Material Size (Max) | 12” x 13” |

| Transport Mechanism | Four 1" friction belts with assist rollers |

| Drop Tray | Included (adds 19" to conveyor length) |

| Optional Features | IR7C infrared dryer, cross-stack guides ('S' version) |

| Duty Cycle | 60 million total / 1 million per month (5-year rating) |

| Electrical | 115VAC or 240VAC, 50/60 Hz |

| Dimensions | 35" L x 15" W x 5" H (plus 19" drop tray) |

| Weight | 50 lbs |

Applications

📨 Mailpiece Output Handling – Transfers finished mail to stacking, drying, or sorting areas

📦 High-Volume Print Runs – Keeps jobs moving smoothly through inline systems

🏢 Compact Mailing Environments – Perfect for businesses needing reliable tabletop automation

Available Options

📍 IR7C Infrared Dryer – Speeds up drying for printed materials and improves print quality

📍 Cross-Stack Kit – Adds alignment guides and dryer mounts for ‘S’ model configuration

Benefits

✅ Streamlines production by automating post-print conveyance

✅ Reduces smudging and wait times with optional drying

✅ Saves space with a lightweight, compact build

✅ Integrates seamlessly with printers, tabbers, and feeders

✅ Built to last with a 5-year, high-volume duty cycle rating

Contact Us