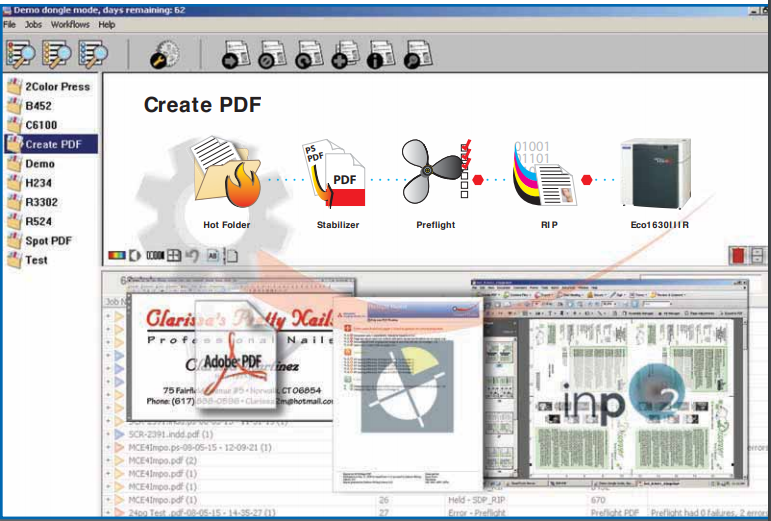

Mitsubishi SDP-Eco1630IIIR — 2-Up Eco Platesetter

Automated CTP with integrated low-chemistry Eco processing. Designed for fast 2-up plates from paper or polyester rolls with excellent quality and low operating cost.

Key Features

🔷 Up to 78 plates/hour at 1200 dpi; resolutions to 2400 dpi

🔷 Eco Processor uses significantly less activator/stabilizer

🔷 Images paper or polyester plates from roll stock and cuts to size

🔷 Screen rulings to 175 lpi with stable, repeatable results

🔷 Compact footprint, 120V wall power

Specifications

| Resolution / Speed | 1200/1500/1800/2400 dpi; up to 78 plates/hr @1200 dpi |

| Plate sizes (min–max) | 9" × 8.65" to 16-5/16" × 29"; max recording width 15.9" |

| Run length | Up to ~10,000 (paper) / ~25,000 (polyester)* |

| Screen ruling / Tint | Up to 175 lpi; 5–95% tints |

| Processing | Integrated Eco Processor; thinner activator/stabilizer layers reduce usage |

| Power / Size / Weight | 100/120 VAC, 15A; 39-3/8" W × 31-5/16" D × 42-1/8" H; ~456 lb |

*Under standard printing conditions.

Applications

📰 Fast 2-up plates for forms, duplicator, and small offset presses

🏷️ Paper or polyester plate workflows with economical chemistry use

Available Options

📌 Rebuilt/used units with existing RIPs (1-bit TIFF compatibility)

📌 New RIP upgrades for Windows 11 as needed

Benefits

✅ High throughput with proven image stability

✅ Lower chemistry consumption cuts ongoing costs

✅ Rebuilt availability offers strong value and faster ROI

Contact Us