Horizon SmartSlitter SMSL-100 Sheet Cutter & Creaser

The Horizon SmartSlitter SMSL-100 is a compact, multi-function sheet processor combining cutting, creasing, perforating, and slitting in one pass. Engineered for high-precision digital finishing, it supports a wide range of applications—from business cards to covers—while offering barcode-driven job automation and camera-based alignment correction for consistent, accurate results.

Key Features

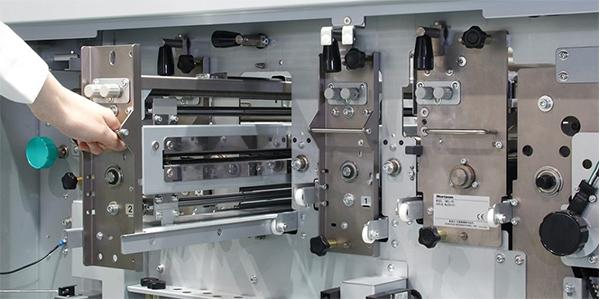

🔷All-in-one operation — Cuts, creases, slits, and perforates in a single pass.

🔷Dual creasing/perforating modes — Impact and rotary tools in both directions.

🔷Camera registration — Detects marks to correct image shift in real time.

🔷Up to 20 impact creases per sheet per pass.

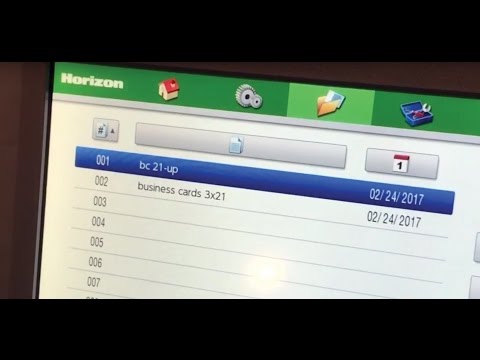

🔷Touchscreen interface — Stores up to 200 job memories.

🔷Ultrasonic sensors — Detect double feeds and misfeeds automatically.

🔷Optional conveyor/stacker — Enables continuous production and easy output handling.

🔷Adjustable crease depth — Fine-tune in 0.1 mm increments.

🔷Versatile output — Ideal for business cards, greeting cards, coupons, and tickets.

Specifications

| Specification | Details |

|---|---|

| Max Sheet Size | 370 × 670 mm (14.56″ × 26.37″) |

| Min Sheet Size | 200 × 200 mm (7.87″ × 7.87″) |

| Max Finished Size | 370 × 670 mm (14.56″ × 26.37″) |

| Min Finished Size | 48 × 50 mm (1.89″ × 1.97″) |

| Sheet Weight Range | 81–370 gsm (varies by module) |

| Max Feeder Stack Height | 150 mm (5.9″) |

| Impact Creasing Lines | Up to 20 per sheet |

| Production Speed | Up to 54 sheets/min (A4) • 48 sheets/min (B3) |

| Voltage | 200–240 V / 208–220 V, Single Phase |

| Rated Current | Approx. 4.5 A |

| Dimensions (Tray Open) | 120″ W × 30.1″ D × 57.9″ H |

| Weight | Approx. 190 kg (419 lb) |

Applications

Benefits

Contact Us