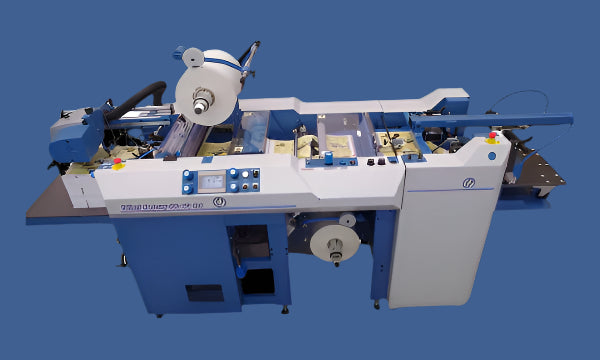

Double-Sided Laminating System

The Foliant Taurus 400 NG 4x4 Double is a compact, industrial-grade double-sided thermal laminator designed for nonstop lamination of digital and offset prints. With speeds up to 131 ft/min, this system supports automatic suction feeding, twin de-curling, bump separation, and laminates up to 4,800 sheets per hour (14” x 20”). It is ideal for production environments requiring high speed, precision, and sheet flexibility, while maintaining a small footprint.

Key Features

🔷 Double-Sided Thermal Lamination – Laminates both sides of the sheet in a single pass.

🔷 Automatic Suction Feeder – OMRON servo-controlled with 21.25" pile capacity and precise electronic overlap adjustment.

🔷 Twin De-Curling Unit – Includes both blade and roller for offset or toner-sensitive stock.

🔷 Integrated Bump Separator – High-speed separation via PLC-controlled rollers with jogger or pallet stacker output.

🔷 Touchscreen with PLC Automation – Easy icon-based navigation—no language setup required.

🔷 Air Shaft Film Mount – Accepts up to 9,842’ of 24–31μm film for fast, clean film handling.

🔷 Heated Chrome Rollers – Dual heated chrome + rubber rollers per side with internal sensors for even temp distribution.

🔷 Compact Format – Fits into tighter spaces while maintaining industrial-level output.

Specifications

| Specification | Details |

|---|---|

| Max Speed | 131 ft/min (single & double sided) |

| Max Throughput | 4,800 SPH (14” x 20”) |

| Max Sheet Size | 15.7” x 27.5” (39.3” with XL module) |

| Min Sheet Size | 12.6” x 7.8” |

| Paper Weight Range | 115 – 600 gsm |

| Film Types | BOPP (24–42μm), PET (20–26μm SS / 20–22μm DS) |

| Overlap Accuracy | ±0.08” (±2 mm) |

| Warm-Up Time | <10 minutes |

| Power Supply | 3-phase, 400V AC, 50–60Hz |

| Power Consumption | 8,900 W |

| Air Requirement | 150 L/min @ 6–8 bar (external compressor) |

| Footprint (w/ jogger) | 41.3” x 122” |

| Machine Weight | 1,323 lbs |

Applications

📚 Book Covers & Manuals – Dual-sided protection for professional finish and durability.

📦 Retail Packaging & Cartons – Clean lamination for folding cartons, sleeves, and inserts.

📄 Flyers, Brochures & Postcards – High-speed finishing for short- or long-run commercial print jobs.

🛍 POP Signage & Product Cards – Lamination of marketing and point-of-sale material.

Available Options

📍 Jogger 400 – Vibrating stacker for 3.9” piles (required if pallet stacker not used).

📍 Integrated Pallet Stacker – Fully automatic stacking up to 27.5” height.

📍 Non-Sticky Pressure Rollers – For windowed sheets or adhesive-sensitive jobs (up to 2X rollers).

📍 Foliant Foiler – Applies metallic foil or spot varnish film over digital toner.

📍 XL Module – Extends max sheet length to 39.3” (manual unload beyond 27.5”).

📍 XXL Feeding Table Extension – Supports sheets up to 51” (manual feeding only).

📍 PET Film Module – Required for processing PET films (20–26μm).

📍 Film Loader / Manipulator – Electric lift for rolls up to 275.5 lbs.

📍 Anti-Static Bar – Removes charge from laminated output for clean stacking.

Benefits

✅ Double-sided lamination in one pass maximizes efficiency and reduces labor.

✅ Perfect for digital and offset jobs thanks to twin de-curl and wide stock support.

✅ Fully automatic operation with programmable overlap, separation, and feed control.

✅ Compact size with scalable upgrades makes it ideal for growing production needs.

✅ Touchscreen simplicity allows for rapid operator training and error-free setup.

Contact Us