AP4 High-Volume In-Line Digital Address Printer

The AP4 High-Volume Digital Address Printer is engineered for production mail environments that demand speed, accuracy, and flexibility. Processing up to 26,000 #10 envelopes or 34,000 postcards per hour with variable print resolutions up to 600 x 600 DPI, the AP4 delivers sharp, professional addressing at high speed.

A robust 2 pen + 4 pen + 2 pen stitched print head design with a 4" H x 50" L imaging area allows you to print the address, return address, indicia, and taglines in a single pass. With an in-line transport deck, up to 16GB of job storage, on-screen ink monitoring, and support for pieces up to 1/2" thick, the AP4 is a workhorse for busy mailrooms, commercial printers, and lettershops.

Key Features

- 🔹 High-volume production — up to 26,000 #10 envelopes/hour or 34,000 postcards/hour

- 🔹 2 pen + 4 pen + 2 pen stitched print head with three independent print head banks

- 🔹 Large imaging area up to 4" H x 50" L for address, return, indicia, and taglines in one pass

- 🔹 Variable print resolutions up to 600 x 600 DPI for crisp text and graphics

- 🔹 Handles media from 5" x 3" to 50" x 15" and up to 12.7mm / 1/2" thick

- 🔹 Duty cycle rated up to 1,250,000 pieces per month for demanding production schedules

- 🔹 Thermal inkjet technology with 8 high-capacity cartridges and on-screen ink monitoring

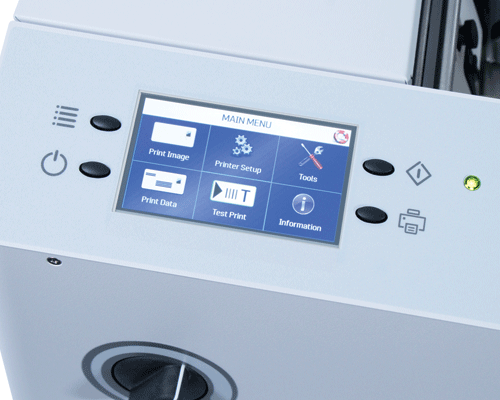

- 🔹 Color touchscreen with adjustable backlight and intuitive navigation

- 🔹 Up to 16GB of job storage for repeat work and saved setups

- 🔹 Designed for in-line use with feeders, transport decks, and existing mailing equipment

- 🔹 Adjustable print head height to accept media up to 1/2" thick

- 🔹 USB 3.0 and Ethernet (LAN) connectivity for modern workflows

Applications

- ✉️ Direct mail addressing on #10 envelopes, flats, and postcards

- 📬 Addressing for statements, invoices, and transactional mail runs

- 🏢 In-plant and corporate mailroom production for recurring campaigns

- 💌 Fundraising, nonprofit, and membership renewal mailings

- 🏫 School, university, and municipal communications and notices

- 📦 Fulfillment and distribution applications printing addresses on thicker pieces up to 1/2"

Specifications

| Print technology | Thermal inkjet, 8 high-capacity cartridges* |

| Addressing speed | Up to 26,000 #10 envelopes/hour; up to 34,000 postcards/hour |

| Print quality | Up to 600 x 600 DPI |

| Imaging area | Up to 4" H x 50" L (102 x 1,270 mm) |

| Material size | Min: 5" L x 3" W (127 x 76 mm) Max: 50" L x 15" W (1,270 x 381 mm) |

| Material thickness | Up to 12.7 mm / 1/2" |

| Duty cycle | Up to 1,250,000 pieces per month |

| Memory | Up to 16GB |

| Print head layout | 2 pen + 4 pen + 2 pen stitched design; three independent print head banks |

| Feeder capacity (optional) | Up to 500 #10 envelopes with AP12 Heavy Duty Friction Feeder |

| Print orientation | Left to right |

| Software / OS | Drivers for Windows 7 and higher |

| PC interface | USB 3.0, Ethernet (LAN) |

| Dimensions (L x D x H) | 34" L x 25" D x 12" H (86 x 64 x 31 cm) |

| Weight | 96 lbs (44 kg) |

| Power | 115VAC, 50/60 Hz |

* Printer ships with 4 AP22 high-capacity ink cartridges. Additional cartridges may be purchased separately.

Available Options

- 📌 AP12 Heavy Duty Friction Feeder — holds up to 500 envelopes

- 📌 AP4F stand-alone system with AP4 and AP12 Feeder

- 📌 AP14 tabletop riser stand for ergonomic configuration

- 📌 Bulk mailer software for address management and postal preparation

- 📌 Thermal inkjet cartridges and spot-color options to match your workflows

Benefits for Your Operation

- Keeps production mail moving with high throughput and a robust duty cycle.

- In-line configuration reduces manual handling and improves registration accuracy.

- Wide imaging area consolidates multiple print elements into a single pass.

- Touchscreen controls and job storage shorten setup time and simplify repeat jobs.

- Handles a broad range of sizes and thicknesses for versatile job changeovers.

- Modular options let you scale from standalone feeding to full production systems as volume grows.

Contact Us