The Horizon VAC-1000 is a modular, high-speed air-suction collator designed for commercial printing, bookletmaking, and bindery applications. With a proven suction rotor feeding system, up to 60-bin capacity, and support for offset and digital print stock, the VAC-1000 provides flexible, mark-free collation with expansion options and seamless integration into Horizon’s inline bookletmaking systems like the StitchLiner and SPF series.

Key Features

🔷 Scalable Configuration – Modular tower system supports up to 6 towers and 60 bins.

🔷 Suction Rotor Feeding – Horizon’s signature system feeds coated, uncoated, and signature stocks smoothly and reliably.

🔷 Double-Feed Detection – Built-in infrared sensors detect and reject misfeeds in real time.

🔷 Sheet Size Versatility – Accepts sheets from 5.83” x 5.83” to 13.77” x 19.68”.

🔷 Advanced Overlap Control – Four-step overlap adjustment ensures precise stacking and feeding alignment.

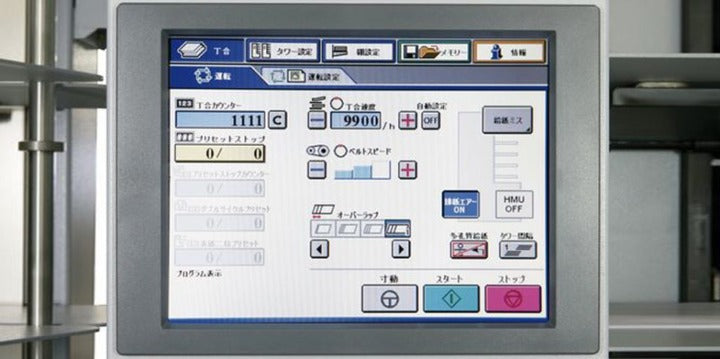

🔷 User-Friendly Touchscreen – Graphical interface with job memory and wireless remote control.

🔷 Inline Integration Ready – Designed to connect with StitchLiner, SPF/FC series, and Horizon trimmers for fully automated booklet production.

🔷 Custom Programming Modes – Supports block feed, double-cycle, and dual cover feeding for high-quality booklet folding and cover handling.

Specifications

| Specification | Details |

|---|---|

| Max Sheet Size | 13.77” x 19.68” (350 x 500 mm) |

| Min Sheet Size | 5.83” x 5.83” (148 x 148 mm)* |

| Sheet Weight Range | Normal: 52.3 – 207 gsm |

| Coated: 73.3 – 207 gsm | |

| 8-page signature: up to 104.7 gsm | |

| Max Bin Stack Height | 55 mm (2.16”) / 11 kg (24.3 lbs) |

| Feeding System | Suction Rotor |

| Max Bins Per System | 60 (6 towers of 10 bins each) |

| Production Speed | Up to 9,900 sets/hr (10-bin config) |

| Up to 4,000 sets/hr (60-bin config) | |

| Power Requirements | Single Phase, 208–240V, 50/60 Hz |

| Dimensions (per tower) | 34.0”–37.3” W × 25.7” D × 77.3” H |

* With optional guide installed, min width is 4.73” (120 mm).

Applications

📚 High-Volume Bookletmaking – Reliable collation of sheets for inline stitching, folding, and trimming.

🖨 Offset & Digital Print Finishing – Feeds a wide range of stocks from digital presses and offset runs.

📑 Manual Set Preparation – Output collated stacks for manual binding or insertion.

🏷 Signature Insertion – Supports thick and 8-page folded signatures for publishing workflows.

Available Options

📍 ESB-L1000 Extra Side Blower – Ensures stable feeding of large or heavy sheets.

📍 EAB-1000 Extra Air Blower – Optimized for feeding coated papers.

📍 LG-1000 A4 Landscape Kit – Expands max sheet length to 24” (610 mm) for A4 landscape production.

📍 IC2-V600 Image Checker – Detects missing or mis-sequenced sheets using visual page scanning.

📍 SW-20 / ST-60 Receiving Trays – Choose criss-cross or stacker trays depending on output needs.

📍 PJ-77 Jogger – Vibrates stacks into aligned sets for downstream processing.

📍 BC-20 Bypass Conveyor – Switch easily between bookletmaking and straight stacking.

Benefits

✅ Feeds diverse stocks including coated, folded, and digital media with mark-free reliability.

✅ Boosts throughput with up to 60 bins and advanced feed switching modes.

✅ Reduces downtime via automated misfeed detection and overlap control.

✅ Enhances output quality with fine overlap settings and jogged stack delivery.

✅ Seamlessly integrates into Horizon's end-to-end finishing systems.

Contact Us