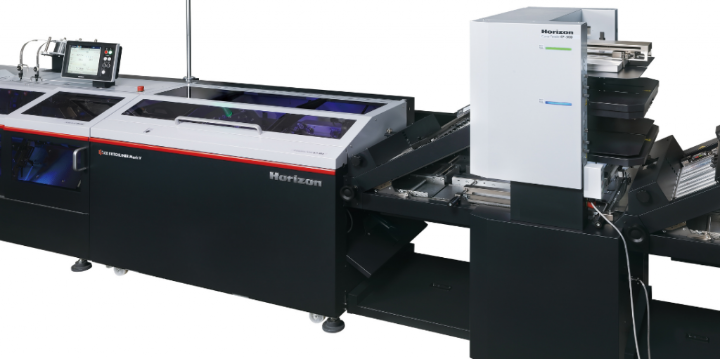

Horizon iCE StitchLiner Mark V Saddle-Stitching System

The iCE StitchLiner Mark V is Horizon’s most advanced in-line saddle-stitching system, engineered for high-speed, fully automated booklet production from either roll-fed or cut-sheet inputs. Supporting book-of-one production, variable thickness, and complex configurations—cover insertion, scoring, folding, stitching, trimming—it provides end-to-end automation through its touchscreen interface and iCE LiNK workflow integration.

Key Features

🔷6,000 Booklets / Hour — High-speed, automated stitching from flat sheets.

🔷Variable Thickness Binding — Adjusts stitch length, pressure, and trim per booklet.

🔷Flexible Feeding Modes — Accepts roll-fed or HSF-50 cut-sheet input.

🔷Full Job Automation — 12.1″ touchscreen setup with 999 stored jobs.

🔷Inline 3-Knife Trimmer — Automated fore-edge, top, and bottom trimming with joggers.

🔷Multi-Position Insertion — Insert up to three sheets with cover matching.

🔷Precise Scoring & Folding — Clean, accurate spines and folds every cycle.

🔷Tracking & Verification — Barcode-based sheet control and reject handling.

🔷Loop, Center, 3 or 4 Stitching — Configurable heads for all formats.

🔷iCE LiNK Connectivity — Real-time analytics and cloud workflow automation.

Specifications

| Specification | Details |

|---|---|

| Max Speed | 6 000 booklets/hr (Portrait) | 5 300/hr (Landscape) |

| Finished Size Range | Max 13.85 × 11.92″ | Min 4.72 × 3.35″ |

| Max Sheet Size | 24.015 × 14.015″ |

| Max Booklet Thickness | 10 mm (~50 sheets of 81.4 gsm) |

| Sheet Weight Range | 52.3–209 gsm (roll) | 52.3–350 gsm (cover) |

| Stitching Options | 2 / 3 / 4 heads + loop stitching available |

| Trim Range | Fore, top, bottom 2–25.4 mm |

| Controller Interface | 12.1″ touchscreen with 999 job memory |

| Cover Feeder | Optional CF-50D | Up to 15 000 A4 sheets/hr |

| Feeding Options | Roll-fed (unwinder + cutter) | HSF-50 cut-sheet |

| Power Requirements | 3-Phase 200–230 / 380–415 V, 50/60 Hz |

Applications

Available Options

Benefits

Contact Us